Cleanrooms: all you need to know.

Read this interesting text from Delta 2000, the international player in cleanroom production.

1. Cleanroom: meaning and origin

The cleanroom is also called the “clean laboratory”. All clean rooms are used in industrial and scientific research and as a chemical, mechanical and/or electronic laboratory.

The main feature that distinguishes every cleanroom is the presence of pure air, with a very low content of microparticles of dust in suspension. This is guaranteed thanks to the forced recirculation in a sealed environment compared to the outside.

The English expression “cleanroom” is widely used and spread internationally.

But, what exactly is a cleanroom?

We can define it as a “room” with a controlled atmosphere: the main reference values are atmospheric pressure, humidity and particulate pollution.

It is essential not to confuse, however, the clean room with the hyperbaric chamber (with controlled pressure), with sterile chambers (microbiologically controlled) or, again, with the anechoic chambers that, instead, screen electromagnetic or sound signals.

All cleanrooms produced by Delta 2000 are designed for use in areas with controlled contamination and are intended for multiple sectors: Pharmaceutical, Biomedical, Chemical, Cosmetic and Food.

Without forgetting the structured projects for the hospital sector. Sector, as anticipated, that represents the origin of the same.

2. Operation of the clean rooms

The operation of a clean room is based on the principle of forced recirculation of super-filtered air in a sealed room.

The system consists of large fans operating at low speed, which introduce into the room, through the ceiling, a laminar flow of air already previously filtered by HEPA filters (High-Efficiency Particulate Air Filter) and sucked through grids placed on the floor.

The direction of the flow intake divides the clean rooms into:

- Clean rooms with turbulent flow

- Vertical unidirectional flow clean room

3. Cleanroom classifications and standard regulations

The pioneers of this technology are the Americans, and for this reason, the first law of classification was born in the U.S.A., US Federal Standard 209E, published in 1963 under the name of “Cleanroom and Work Station Requirements, Controlled Environments”.

The other most relevant standard for the measurement and classification of clean rooms are:

- UNI EN ISO 14644-1

- British Standard 5295

- EU GMP

- VDI 2083

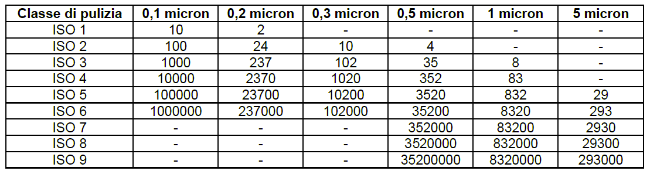

Among all, what is considered the reference, at the global level, is the UNI EN ISO 14644-1. It defines the maximum concentrations of particles contained in a cubic meter of air, in relation to the different classes of cleaning.

4. Use of cleanrooms

The origins of the use of cleanrooms are to be attributed to the first microelectronics industries, in particular, they were used for semiconductor processing. This industry increasingly needed to improve both production efficiency and product quality, in terms of purity.

The solution was to develop and use controlled contamination environments.

In the semiconductor process, in fact, the particles suspended in the air (micro-powders) risk irreparably damaging the micro-photo incisions that form the chips, creating a faulty electronic circuit and, consequently, a waste of product.

The development of industrial processes has imposed the improvement of production environments, eliminating particles from the air, with two main purposes:

- Increase in the production efficiency

- Quality increase

The classification of cleanrooms is based on counting microparticles into a defined volume of air.

Was our first content interesting for you?

Keep following us to find out our next information!

Request information

Are you interested in receiving information about one of our products?

Fill in the form, our Sales Team will contact you as soon as possible.