Cleanroom GLAZED DeltaWALL LIGHT

Cleanroom GLAZED DeltaWALL LIGHT

The walls GLAZED DeltaWALL LIGHT are used for numerous applications in various sectors:

Pharmaceutical, Biomedical, Chemical, Cosmetic and Food, without forgetting the structural projects of hospitals.

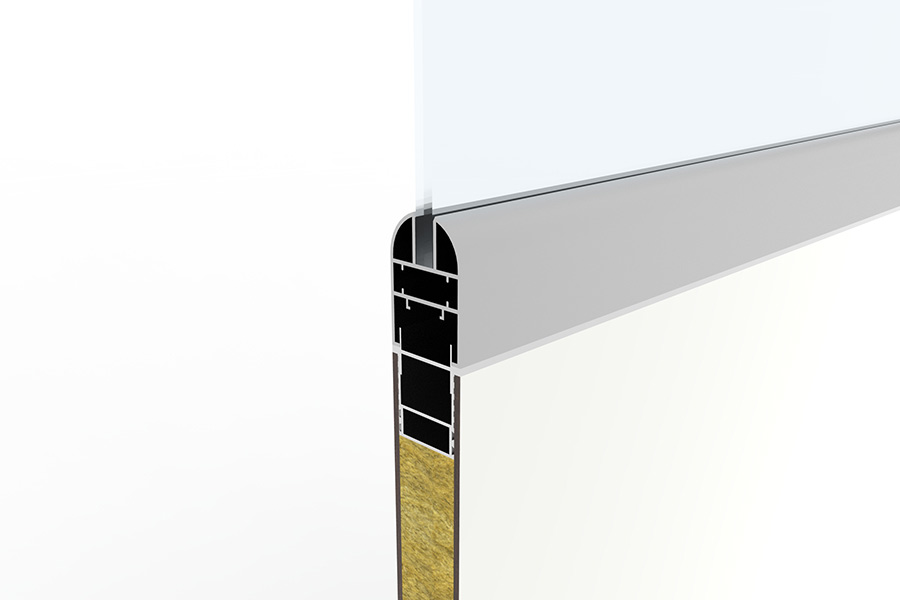

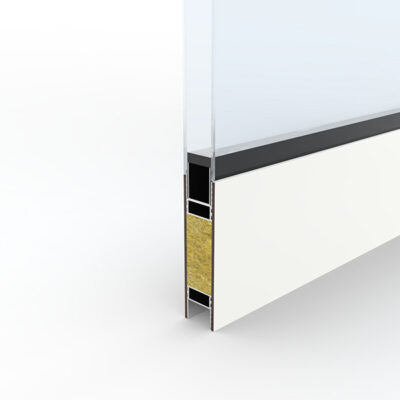

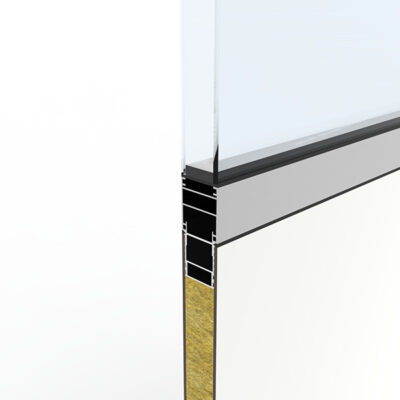

GLAZED DeltaWALL LIGHT glass walls are made from accident-prevention double glazing 6 + 6 mm, for a total thickness of 12 mm.

The glaze is mounted on anodized or painted extruded aluminium profiles and has the following features:

- Width 2mm

- Connectors between double-glazed panel and panels with retractable H profiles, 2 mm wide in raw aluminium

- 4mm visual joint between the panels, sealed with silicone for a total thickness of 48 mm

The laminated glass for safety is made by assembling two or more layers of glass, with one or more sheets of material or plastic interlayer (PVB, PU, PC, SGP, etc.), to achieve better impact resistance.

The plastic film prevents the shatter-proof glass from dispersing its fragments in case of breakage, preventing splinter wounds and delaying or preventing the intrusion of malicious people.

Technical information

| MODULAR PANEL | TECHNICAL DESCRIPTION AND SPECIFICATIONS |

|---|---|

| Reaction to fire | NPD |

| Sound insulation (dB) | NPD |

| Weight (Kg / sqm) | 15.30 |

| Realization times | NON STANDARD COLOURS: aluminium delivery time is 3 weeks. 4/5 weeks from design approval, STANDARD COLOURS: 4/5 weeks from design approval |

| EXTERNAL COVERING | TECHNICAL DESCRIPTION AND SPECIFICATIONS |

| Rivestimento esterno | Galvanized steel sheet |

| Thickness | 0.6 – 0.7 mm |

| Reaction to fire | Class A1 |

| Brillantezza (Gloss) | NPD |

| Impact resistance | NPD |

| Bend resistant | NPD |

| Laminated | NPD |

| INTERNAL FRAME | Perimeter "C" profile in extruded aluminum sp. 2 mm with double reinforcement rib cut at 45 ° and assembled with aluminum brackets. |

| INSULATION | TECHNICAL DESCRIPTION AND SPECIFICATIONS |

| Coibente | Polystyrene flexural strength KPa > 250 |

| Thickness | 45 mm |

| Reaction to fire | Class E EN 13501-1 |

| Thermal conductivity λD (W / mk) | 0.033 EN 12667 |

| Categories Certifications | ASTM, BSI, CE, EUROPEAN NORM EN, GMP, ISO |

| Certifications | UNE EN ISO 12543-1,3,4,5,6:2000, UNI EN ISO 12543-2:2006 |

Cleanroom GLAZED DeltaWALL LIGHT

The walls GLAZED DeltaWALL LIGHT are used for numerous applications in various sectors:

Pharmaceutical, Biomedical, Chemical, Cosmetic and Food, without forgetting the structural projects of hospitals.

GLAZED DeltaWALL LIGHT glass walls are made from accident-prevention double glazing 6 + 6 mm, for a total thickness of 12 mm.

The glaze is mounted on anodized or painted extruded aluminium profiles and has the following features:

- Width 2mm

- Connectors between double-glazed panel and panels with retractable H profiles, 2 mm wide in raw aluminium

- 4mm visual joint between the panels, sealed with silicone for a total thickness of 48 mm

Technical information

| MODULAR PANEL | TECHNICAL DESCRIPTION AND SPECIFICATIONS |

|---|---|

| Reaction to fire | NPD |

| Sound insulation (dB) | NPD |

| Weight (Kg / sqm) | 15.30 |

| Realization times | NON STANDARD COLOURS: aluminium delivery time is 3 weeks. 4/5 weeks from design approval, STANDARD COLOURS: 4/5 weeks from design approval |

| EXTERNAL COVERING | TECHNICAL DESCRIPTION AND SPECIFICATIONS |

| Rivestimento esterno | Galvanized steel sheet |

| Thickness | 0.6 – 0.7 mm |

| Reaction to fire | Class A1 |

| Brillantezza (Gloss) | NPD |

| Impact resistance | NPD |

| Bend resistant | NPD |

| Laminated | NPD |

| INTERNAL FRAME | Perimeter "C" profile in extruded aluminum sp. 2 mm with double reinforcement rib cut at 45 ° and assembled with aluminum brackets. |

| INSULATION | TECHNICAL DESCRIPTION AND SPECIFICATIONS |

| Coibente | Polystyrene flexural strength KPa > 250 |

| Thickness | 45 mm |

| Reaction to fire | Class E EN 13501-1 |

| Thermal conductivity λD (W / mk) | 0.033 EN 12667 |

| Categories Certifications | ASTM, BSI, CE, EUROPEAN NORM EN, GMP, ISO |

| Certifications | UNE EN ISO 12543-1,3,4,5,6:2000, UNI EN ISO 12543-2:2006 |

Related products

Related products

-

GLAZED DeltaWALLS

Cleanroom GLAZED DeltaWALL CLEAN

-

GLAZED DeltaWALLS

Cleanroom GLAZED DeltaWALL 55