HPL DeltaWALL Honeycomb insulation

HPL DeltaWALL Honeycomb insulation

Aluminium honeycomb insulation for HPL modular panels are used for various functions in a multitude of sectors:

Pharmaceutical, Biomedical, Chemical, Cosmetic and Food, without forgetting the structural projects of hospitals.

Aluminium honeycomb insulation is used for modular panels such as wall panels, floors, ceilings and pharmaceutical doors.

The benefits of aluminium honeycomb insulation for modular panels include:

- Lightness

- Rigidity

- Fire resistant

- Compression, trim and corrosion resistant

- Flat surface

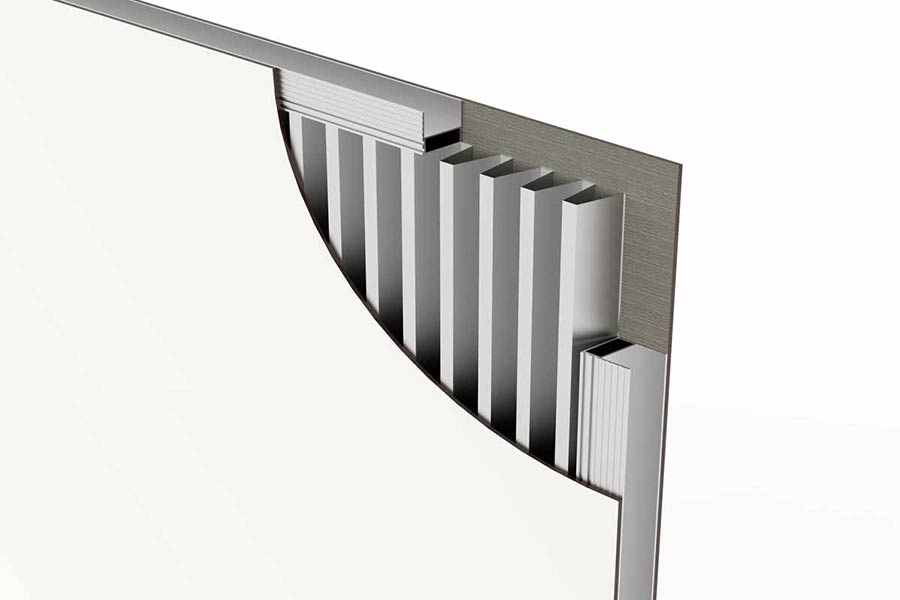

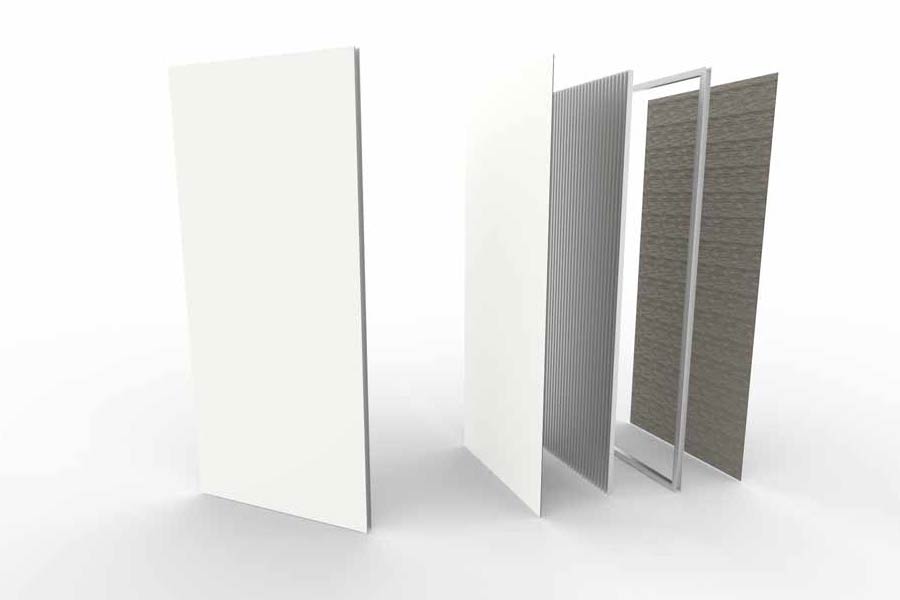

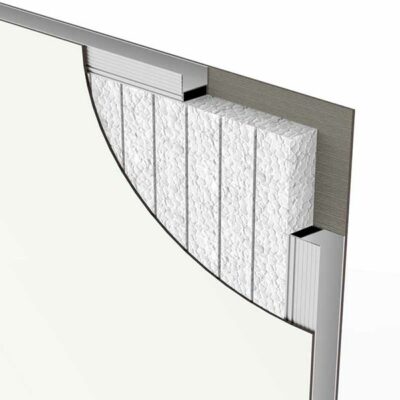

The modular walls HPL DeltaWALL™ HONEYCOMB with honeycomb insulation are made of:

- Internal frame in extruded raw aluminium, 2 mm thick, insulated with honeycomb aluminium / corrugated aluminium sheets

- 4 mm HPL external coating, with a total panel thickness of 48 mm

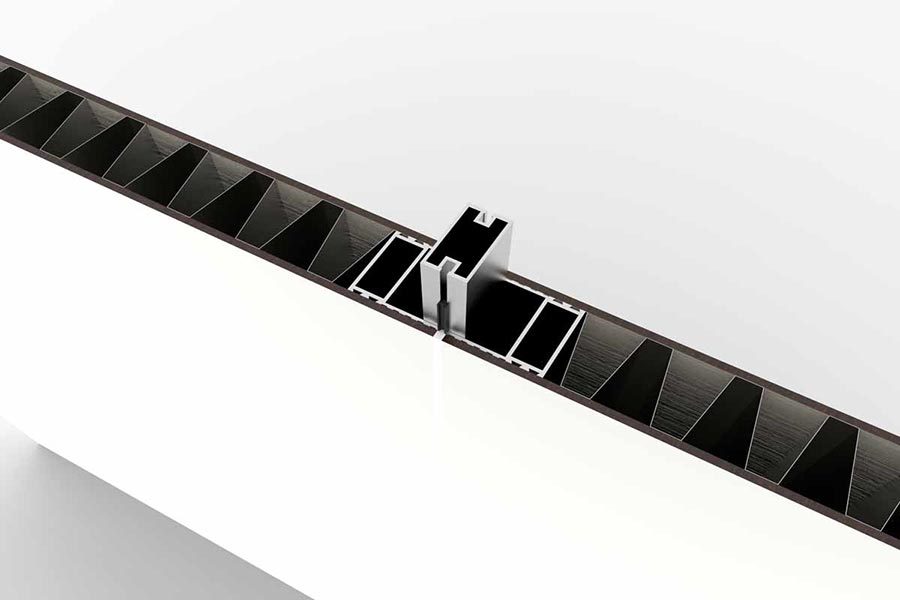

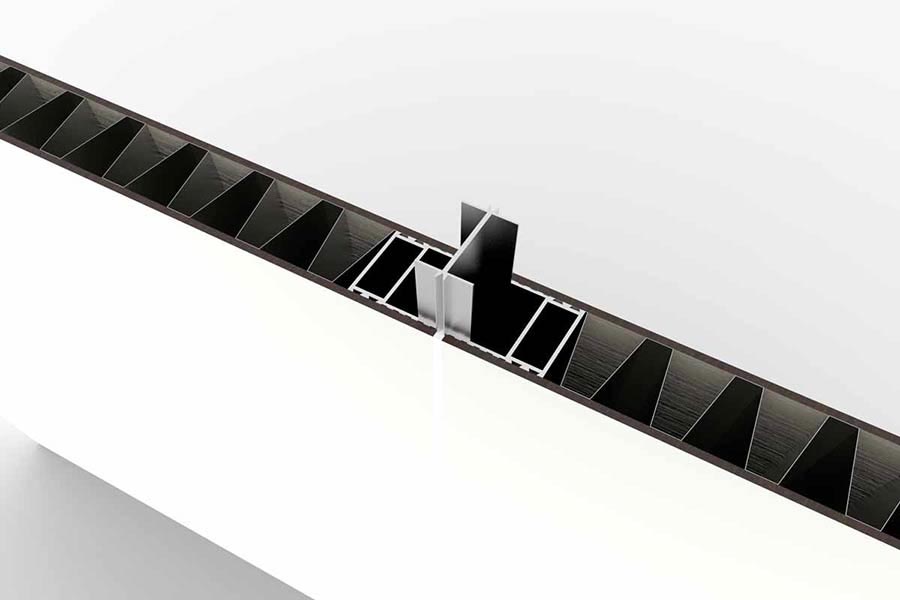

- Vertical H-shaped aluminium extrusion bar (2 mm thick) to mount the panels together, with a maximum width of 4 mm between the panels. To be fixed with silicone and raw aluminium profiles anchored to existing floors

Technical information

| MODULAR PANEL | TECHNICAL DESCRIPTION AND SPECIFICATIONS |

|---|---|

| Reaction to fire | Class B.s1-d0 |

| Sound insulation (dB) | Rw (C;Ctr)=21(-1;-2) dB |

| Weight (Kg / sqm) | 15.30 |

| Rivestimento esterno | HPL (High Pressure Laminate) |

| Realization times | NON STANDARD COLOURS: laminate delivery time is 8 weeks. 4/5 weeks from design approval, STANDARD COLOURS: 4/5 weeks from design approval |

| EXTERNAL COVERING | TECHNICAL DESCRIPTION AND SPECIFICATIONS |

| Thickness | 4 mm |

| Reaction to fire | Class B,s1-d0 |

| Release of formaldehyde | Class E1 |

| Abrasion resistance | Revolutions: IP > 150 EN 438-2.10 |

| Scratch resistance | Strength: Grade > 3 EN 438-2.25 |

| Impact resistance | Tested with a small diameter ball. Spring force: N>20 EN 438-2.20 |

| INTERNAL FRAME | Perimeter "C" profile in extruded aluminum sp. 2 mm with double reinforcement rib cut at 45 ° and assembled with aluminum brackets. |

| INSULATION | TECHNICAL DESCRIPTION AND SPECIFICATIONS |

| Coibente | Corrugated aluminium sheet Density 116 Kg/m³ |

| Thickness | 40 mm |

| Reaction to fire | Class A1 EN 13501-1 |

| Thermal conductivity λD (W / mk) | NPD EN 12667 |

| Certifications | ASTM E84-18b, EN 13501-1:2007+A1:2009, EN 438-4 |

| Standard colors | 405 White Porcelain, 414 Sand, 854 Bleu Silver, ABET 406 SPRING WHITE |

| Non-standard colors | 1819 Monviso Grey, 1822 Cavallino Red, 1823 Maquis Green, 1824 Amorgos Blue, 1832 Storm Grey, 412 Ivory, 421 Black, 427 Magenta, 469 African Yellow, 859 Faenza Blue |

HPL DeltaWALL Honeycomb insulation

Aluminium honeycomb insulation for HPL modular panels are used for various functions in a multitude of sectors:

Pharmaceutical, Biomedical, Chemical, Cosmetic and Food, without forgetting the structural projects of hospitals.

Aluminium honeycomb insulation is used for modular panels such as wall panels, floors, ceilings and pharmaceutical doors.

The benefits of aluminium honeycomb insulation for modular panels include:

- Lightness

- Rigidity

- Fire resistant

- Compression, trim and corrosion resistant

- Flat surface

Technical information

| MODULAR PANEL | TECHNICAL DESCRIPTION AND SPECIFICATIONS |

|---|---|

| Reaction to fire | Class B.s1-d0 |

| Sound insulation (dB) | Rw (C;Ctr)=21(-1;-2) dB |

| Weight (Kg / sqm) | 15.30 |

| Rivestimento esterno | HPL (High Pressure Laminate) |

| Realization times | NON STANDARD COLOURS: laminate delivery time is 8 weeks. 4/5 weeks from design approval, STANDARD COLOURS: 4/5 weeks from design approval |

| EXTERNAL COVERING | TECHNICAL DESCRIPTION AND SPECIFICATIONS |

| Thickness | 4 mm |

| Reaction to fire | Class B,s1-d0 |

| Release of formaldehyde | Class E1 |

| Abrasion resistance | Revolutions: IP > 150 EN 438-2.10 |

| Scratch resistance | Strength: Grade > 3 EN 438-2.25 |

| Impact resistance | Tested with a small diameter ball. Spring force: N>20 EN 438-2.20 |

| INTERNAL FRAME | Perimeter "C" profile in extruded aluminum sp. 2 mm with double reinforcement rib cut at 45 ° and assembled with aluminum brackets. |

| INSULATION | TECHNICAL DESCRIPTION AND SPECIFICATIONS |

| Coibente | Corrugated aluminium sheet Density 116 Kg/m³ |

| Thickness | 40 mm |

| Reaction to fire | Class A1 EN 13501-1 |

| Thermal conductivity λD (W / mk) | NPD EN 12667 |

| Certifications | ASTM E84-18b, EN 13501-1:2007+A1:2009, EN 438-4 |

| Standard colors | 405 White Porcelain, 414 Sand, 854 Bleu Silver, ABET 406 SPRING WHITE |

| Non-standard colors | 1819 Monviso Grey, 1822 Cavallino Red, 1823 Maquis Green, 1824 Amorgos Blue, 1832 Storm Grey, 412 Ivory, 421 Black, 427 Magenta, 469 African Yellow, 859 Faenza Blue |

Related products

Related products

-

HPL DeltaWall

HPL DeltaWall Rockwool

-

HPL DeltaWall

HPL DeltaWALL Polystyrene