Medical Sector

Production and design of clean rooms for the hospital and medical sector

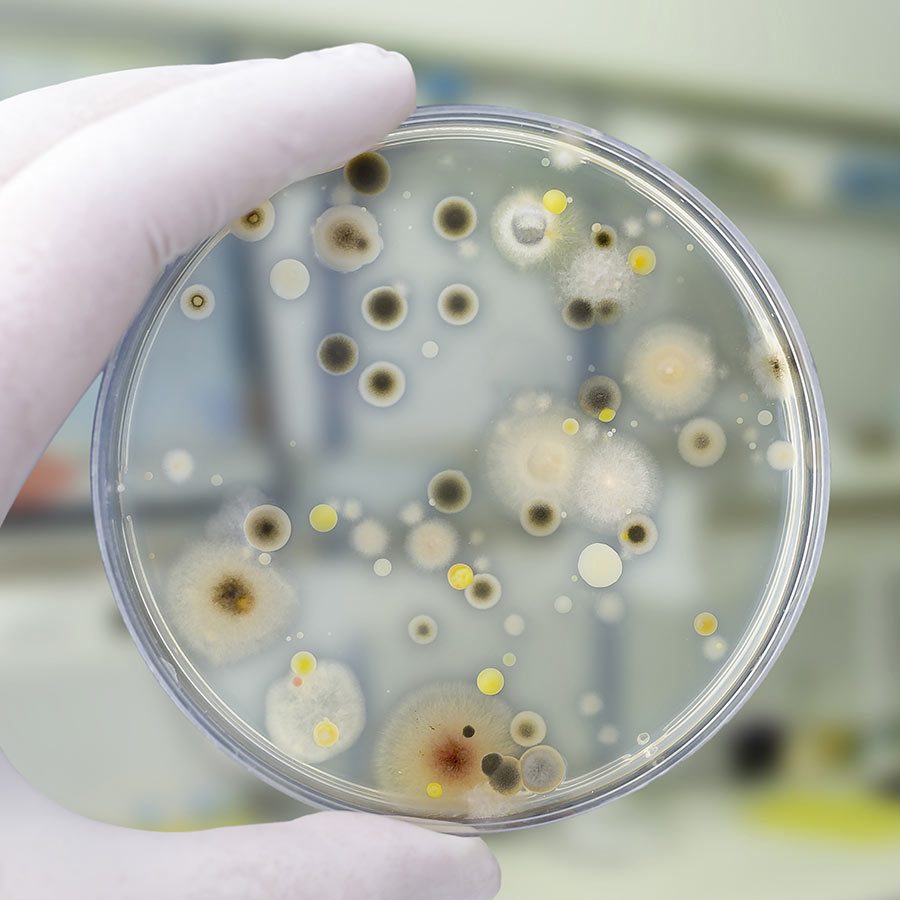

The sterile cleanroom is an essential environment in specific production areas of many types of industry, including the pharmaceutical and hospital sectors. The objective of sterile cleanrooms, always achieved through appropriate design and construction of the environments, is to achieve and maintain optimal conditions not only for the production cycle, but also for the well-being of the operators working inside.

The sterile clean room is characterized by absolute contamination control, and the type of contaminants to be controlled naturally differs depending on the production process and the industry in question. Therefore, each project must be evaluated individually, always taking into account its parameters, requirements, and specific needs.

Delta2000 is the leading company in the design, production, and installation of sterile clean rooms, which are microbiologically controlled and intended for any production sector, including the pharmaceutical and biomedical industries.

Clean rooms for the hospital sector

Operating Rooms

The hospital clean room is normally used in the biomedical industry and must ensure specific technical characteristics, as well as safety and reliability.

Also known as a “clean laboratory,” the hospital clean room is characterized by the absence of microparticles: it is therefore essential that its design and construction be carried out by a specialized company with considerable know-how and extensive experience in the biomedical sector.

Delta2000 is now the partner of choice for numerous hospitals and medical companies seeking the highest quality assurance in terms of the construction of clean rooms for hospitals. From design to production and installation, our clean rooms are the result of proven technology and solid expertise.

Cleanrooms for hospitals must comply with all regulations relating to materials for the pharmaceutical and medical sectors and are divided into specific classes, depending on the degree of purity of the working air. In any case, every cleanroom must always guarantee a controlled contamination environment and prevent air pollution by microorganisms or polluting particles, and therefore will be characterized by maximum cleanliness and a high-quality filtering ventilation system.

Clean rooms for the medical sector

Workshops

The aseptic clean room is an environment that can be used as a chemical laboratory and is characterized by the absence of contaminated air, i.e., a very low, almost zero content of suspended dust microparticles.

Also known as a cleanroom, it is distinguished by a controlled atmosphere in terms of atmospheric pressure and particle pollution. Its operation is based on the principle of forced recirculation of super-filtered air within a sealed environment.

In aseptic cleanrooms, the air purity can be higher than that of an operating room. Generally, operators in an aseptic cleanroom wear sterile gowns, shoe covers, masks, and caps and are properly trained so as not to compromise the air purity.

Clean rooms for the hospital sector

Radiology

Radiology cleanrooms must comply with the usual purity and air control requirements normally applicable to cleanrooms. It is important to bear in mind the extreme delicacy of the equipment generally used in these environments and the importance of not contaminating it in any way, as this could compromise the results of their operations.

Particles suspended in the air, also known as micro-dust, can cause irreparable damage to electronic circuits: the presence of cleanrooms in radiology is now widely documented, especially for the purpose of improving production environments, efficiency, and performance in terms of quality of results.

Sterile room

An essential environment for the hospital sector

The sterile room is considered a space of primary importance in the hospital environment, and must necessarily be the result of careful preliminary consultation, accurate planning and design, and finally, adequate construction and management.

The sterile room is used in both hospital and pharmaceutical settings and, in general, in all environments that require production protected from sources of pollution, both endogenous and exogenous, i.e., internal or external. The utmost care in the production process within the sterile room must ensure flawless management of all components processed, so as to create high-quality products that are excellent in terms of performance.

Designing and building a sterile chamber in collaboration with a highly qualified company such as Delta2000 means being able to interface with a company that has been operating in the sector for over twenty years and is able to guarantee its clients excellent advice and complete management of the entire project. The clean room offered by Delta2000 is a solid and resistant structure, completely independent and integrable, capable of guaranteeing the purity standards required in both the hospital industry and any other professional field.

Get in touch with the experts at Delta2000 now to design your controlled contamination environment: our goal is to create a sterile chamber, or clean room, designed to minimize the introduction, generation, and retention of airborne particles, thus ensuring maximum safety in contamination-sensitive activities.

Request a consultation now to design the most advanced and high-performance sterile chamber.