Sterile environment cabinets

DeltaFURNITURES™ is the line of cleanroom cabinets manufactured by Delta2000, a company specializing in cleanroom design, production and installation.

Sterile environment cabinets designed for contamination-controlled areas, these cabinets are ideal for various industries, with a focus on the hospital sector.

Made of durable HPL (high-pressure laminate), the perfect material for cleanrooms, they are assembled and milled by hand and edged with special machinery.

DeltaFURNITURES™

Cabinet 1 door

The 1-door sterile environment cabinets manufactured by Delta 2000 provide safe storage of personal items in clean rooms and aseptic environments, preventing contamination.

Used in pharmaceutical, biomedical, chemical, cosmetic, food and hospital industries, they are suitable for storing protective gowns and sterile footwear.

Side, top, bottom panels and shelves are 12 or 20 mm thick, made of fire retardant HPL, assembled and edged by hand with dedicated machinery.

DeltaFURNITURES™

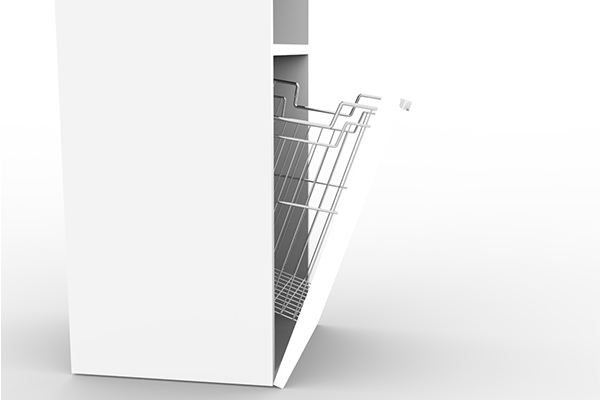

Cabinet 1 door with basket

Similar models with baskets allow for safe storage of sterile clothing and footwear, reducing the risk of contamination in aseptic environments.

Intended for the same sectors, they are built with the same craftsmanship and sturdy materials such as 12 or 20 mm fireproof HPL.

DeltaFURNITURES™

Cabinet 1 door with bench

Some cleanroom cabinets offer built-in benches that provide comfort for staff in cleanrooms.

Sterile clothing and footwear can be stored inside or in the side areas of the bench, promoting greater safety against contamination.

They are made of durable HPL fireproof panels, 12 or 20 mm thick, assembled and edged by hand with special machinery.

DeltaFURNITURES™

Cabinet 2 doors

Sterile room cabinets with 2 doors are designed for safe storage in clean rooms and aseptic environments, ensuring no cross-contamination.

They are particularly suitable for sterile gowns and footwear in industries such as pharmaceutical, biomedical, chemical, cosmetic, food, and hospital.

Like the other models, they are made of fire-retardant HPL with hand assembly and milling and edging done by special machinery.

Delta 2000's cleanroom production cleanroom cabinets are designed for contamination-controlled areas and have applications in many industries.

Sterile environment cabinets

Features, uses and benefits

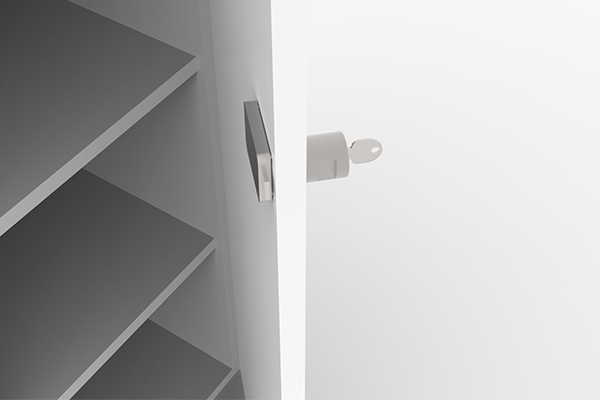

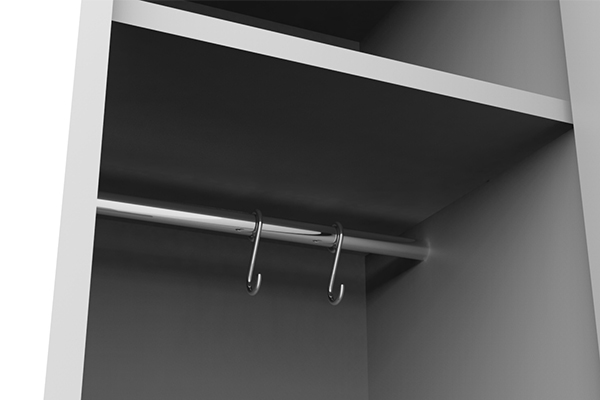

DeltaFURNITURES also offers lockers with functional accessories, such as hygienic ventilation with grilles, flaps, and openings to prevent mold and odor, integrated baskets for used clothing, shelves for valuables and footwear, double-sided lockers with hooks or bars for hanging garments, and internal dividers to separate used and sterile clothing.

Equipped with stainless steel knobs-also lockable-and inclined dust-proof structures, they enable safe handling of sterile clothing and footwear changes while avoiding cross-contamination in cleanrooms.

In summary, Delta 2000’s cleanroom production with the DeltaFURNITURES line provides robust, safe and functional cabinets for all contamination-controlled cleanroom environment needs.

Features and technical description

Available colors

Standard

Non-Standard

DeltaFURNITURES™ Accessories

Delta2000 world leader

Cleanroom Design

During the design phase, the reference sector, type of use, and current regulations are taken into consideration in order to create a layout that meets the highest standards of efficiency and safety. In addition, the integration of the Clean Room into existing processes is also taken into account.

Cleanroom installation

Once designed, built, and tested, the Cleanroom is installed on site. We use our teams of qualified installers with a very high level of professionalism specific to the sector, who fine-tune all the specifications in the project.

Cleanroom Production

The characteristics of our production make our clean rooms unique in many ways: customization and the possibility of non-standard designs; flexibility in terms of timing; use of Italian and European components; and maximum punctuality in delivery.