Galvanized steel sheet panels from Delta 2000, a company specializing in the design and manufacture of cleanrooms and sterile cleanrooms, are suitable for many sectors: pharmaceutical, biomedical, chemical, cosmetic, food, and hospital.

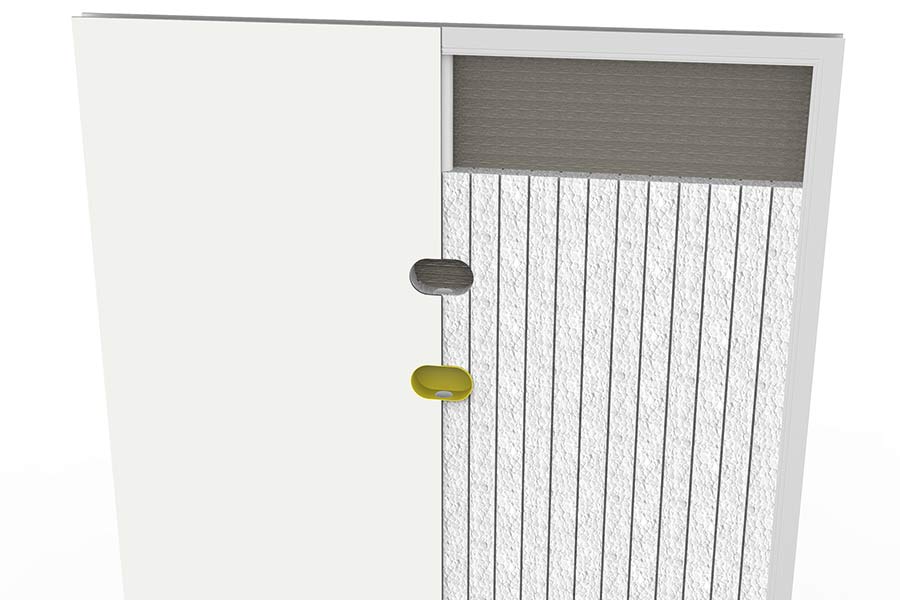

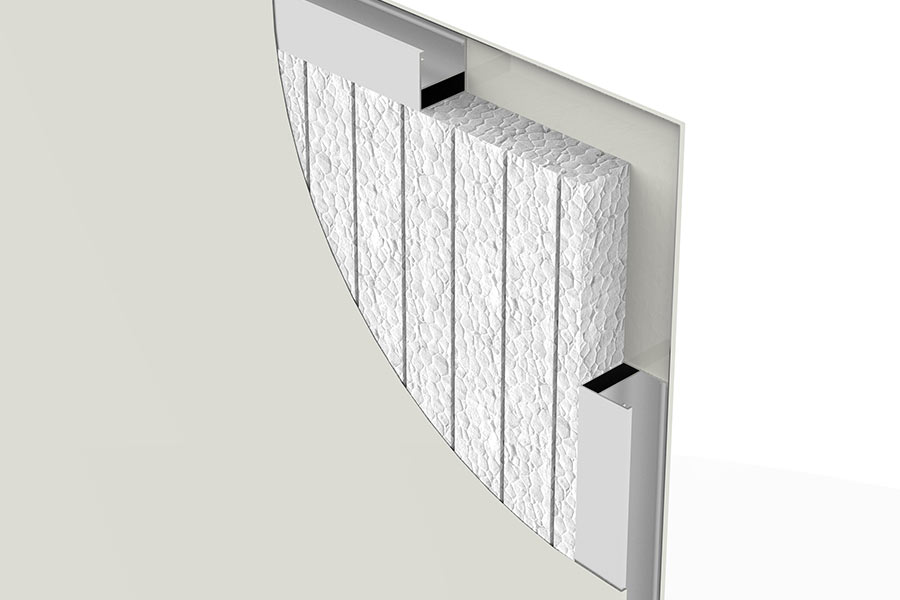

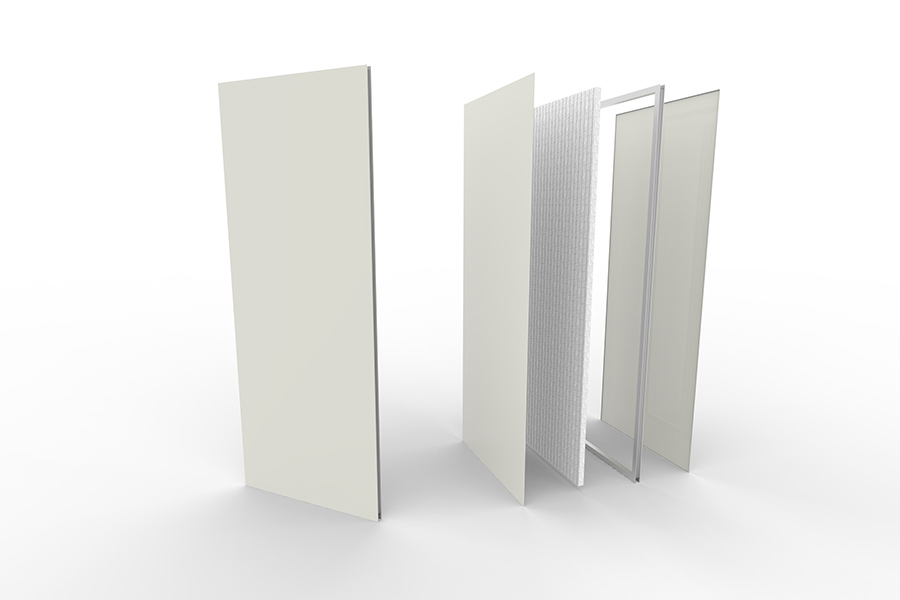

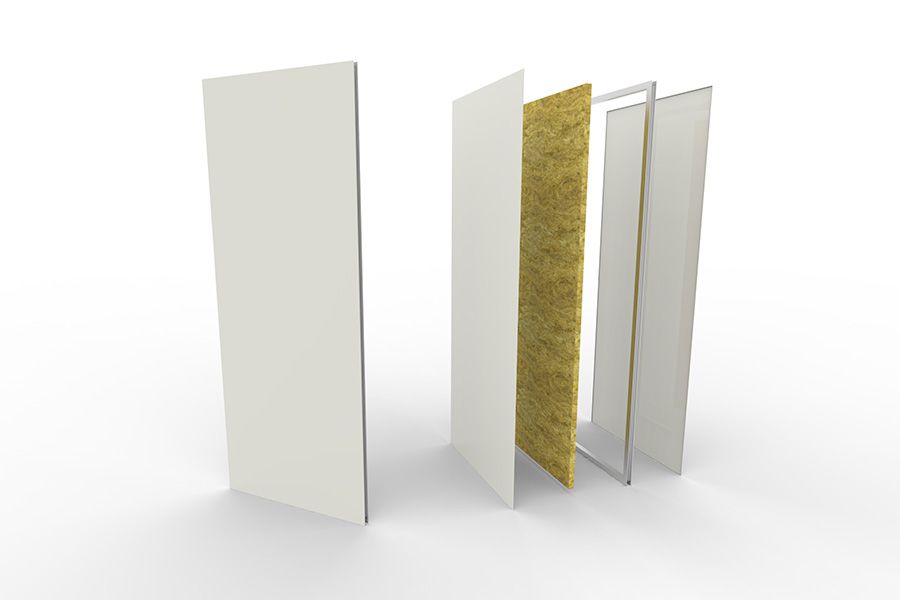

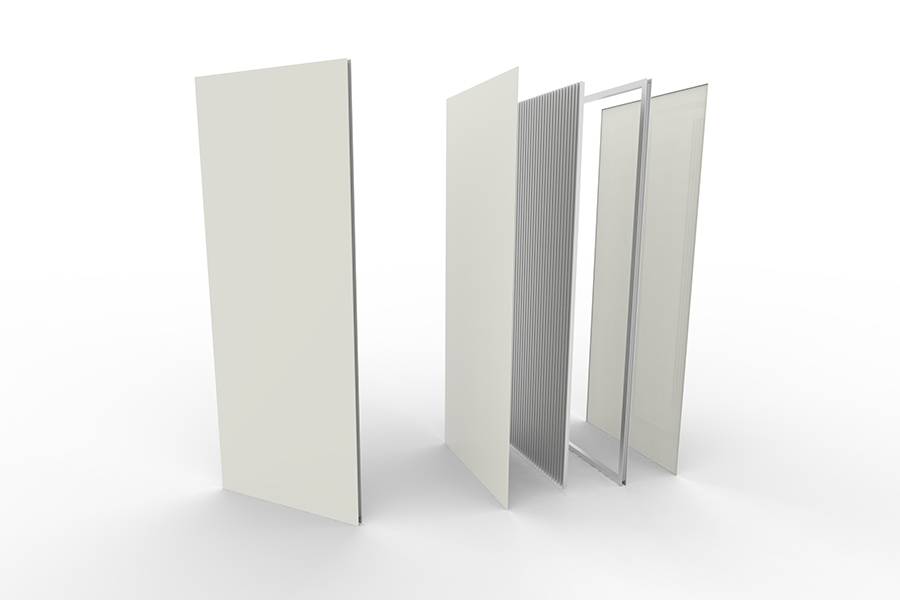

The modular wall has an inner frame of extruded aluminum, insulated with honeycomb, polystyrene or rock wool, and the outer side is 7/10 painted galvanized steel.

Total thickness is 48 mm, with cold-welded joints and aluminum profiles for floor installation.

Delta 2000 also offers galvanized steel panels as an alternative.

These durable and versatile panels offer corrosion protection and are especially ideal for the pharmaceutical, cosmetic and food industries.

Steel DeltaWALL™

Insulating Polystyrene

STEEL modular panel polystyrene insulators are used in various industries: pharmaceutical, biomedical, chemical, cosmetic, food, and hospital.

Suitable for walls, floors, ceilings and pharmaceutical doors, closed-cell sintered expanded polystyrene panels (class E, UNI EN 13163 standards, CE marking) offer good mechanical strength.

Advantages: high insulating power, stability, vapor permeability, water resistance, mold and bacterial attackability.

STEEL DeltaWALL™ POLYSTYRENE modular walls have:

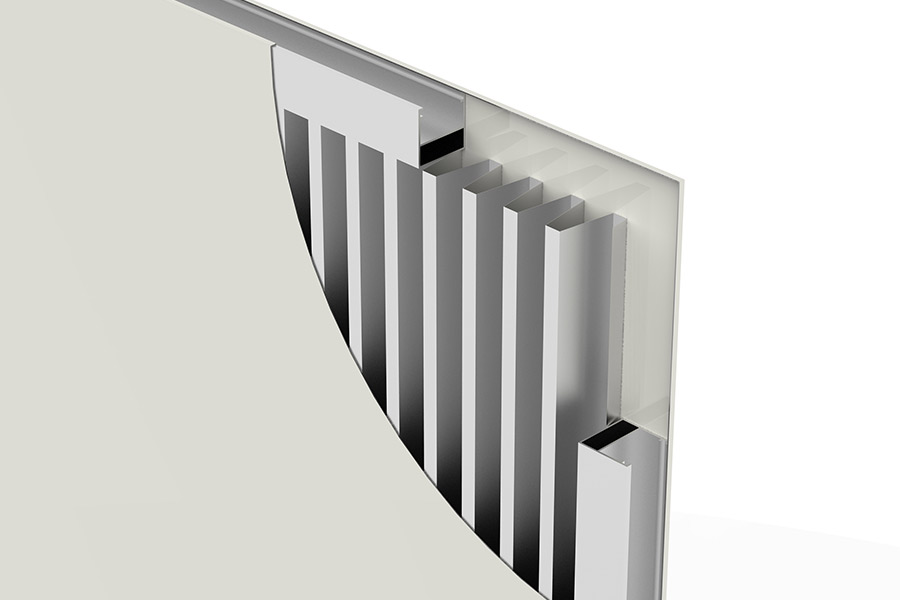

- 2 mm extruded aluminum inner frame, insulated with honeycomb aluminum or corrugated sheet metal

- Galvanized sheet metal exterior cladding, total thickness 48 mm

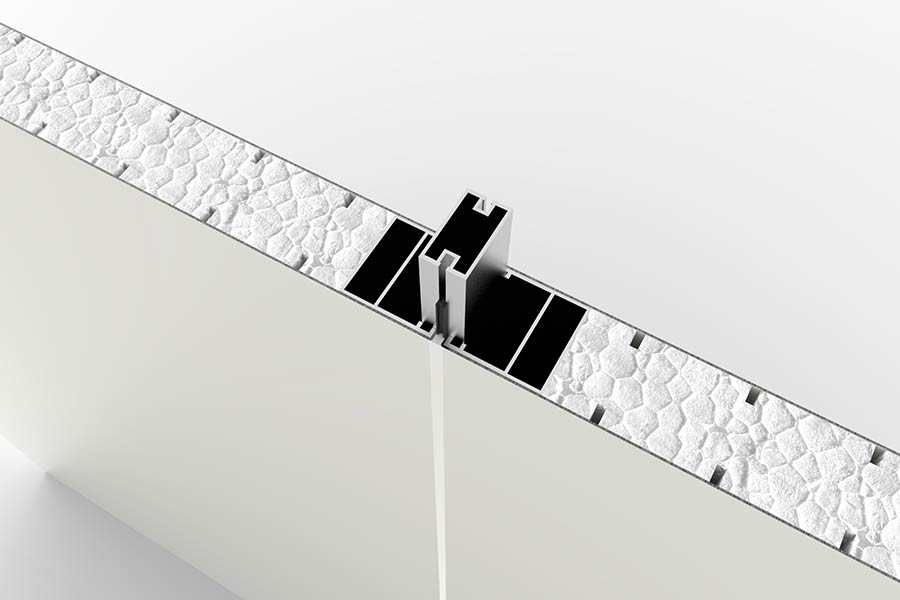

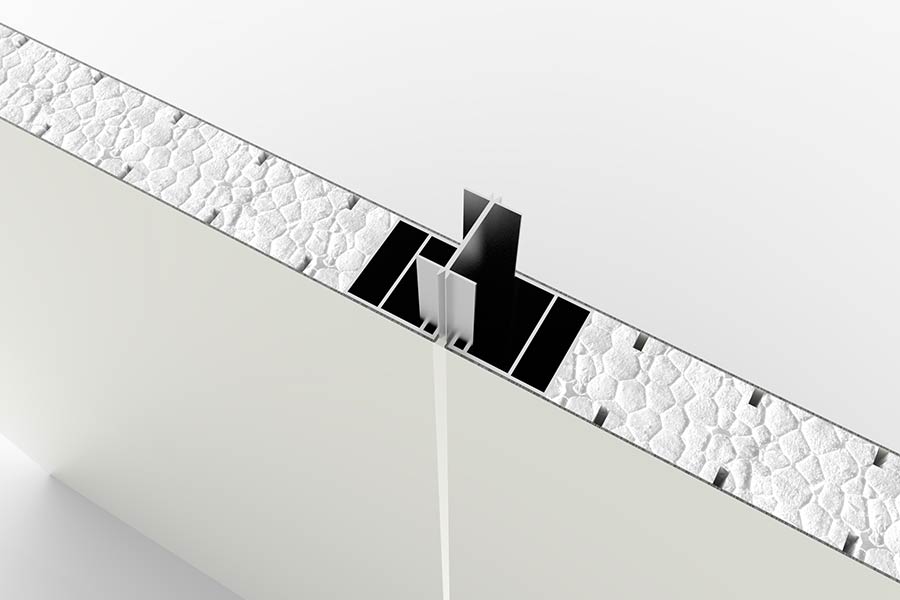

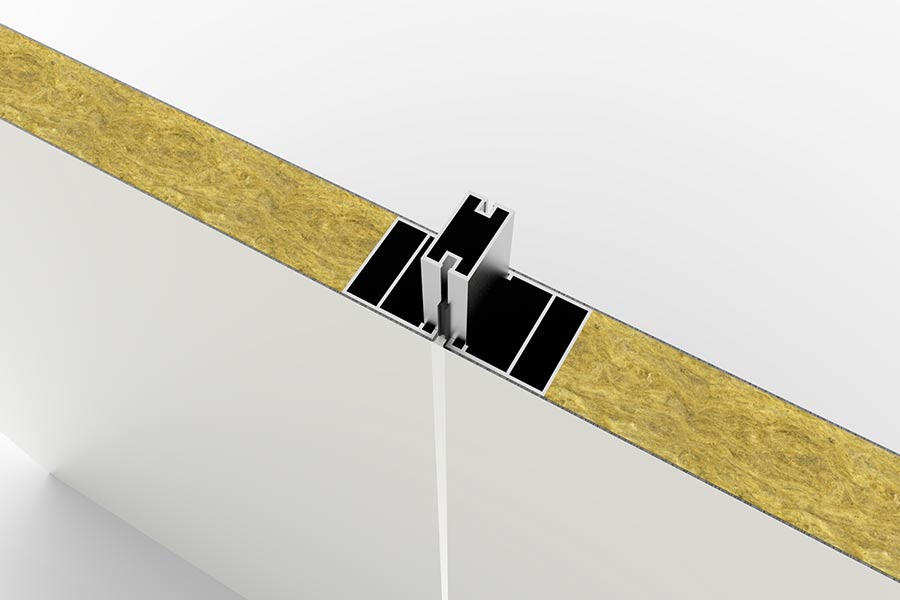

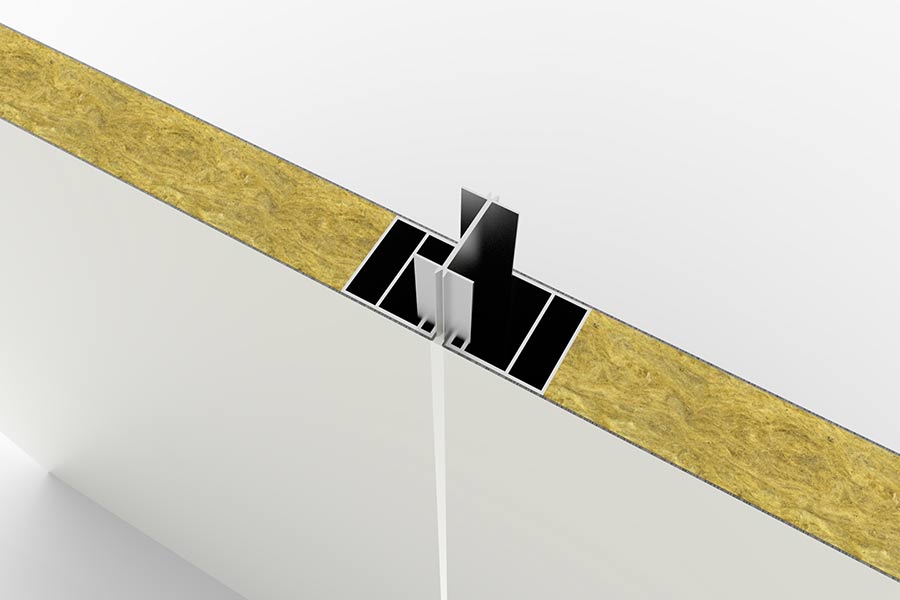

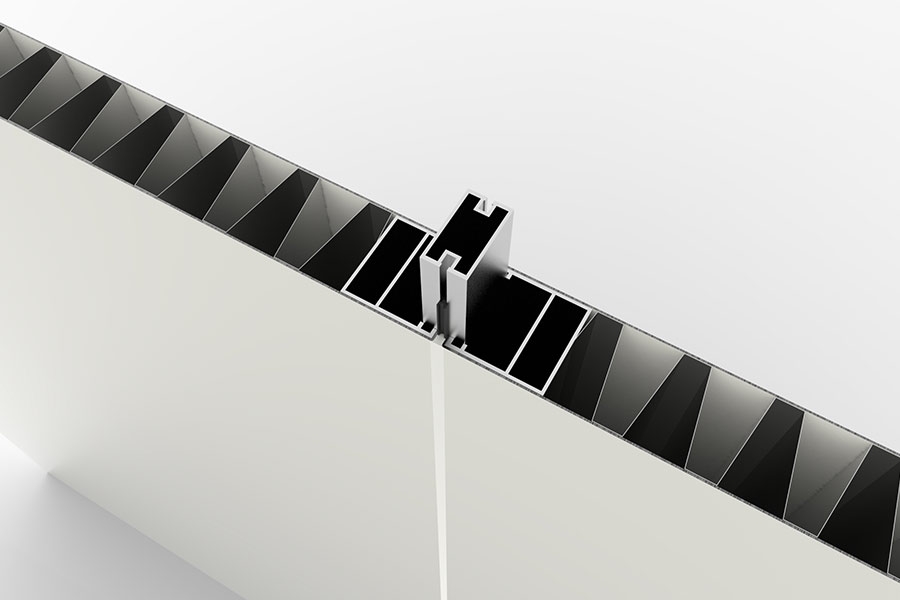

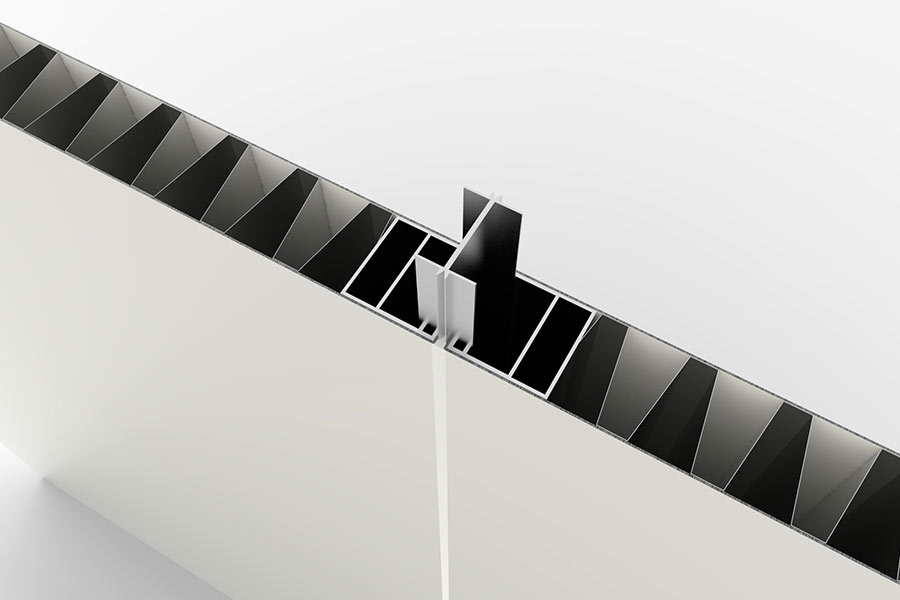

- 2 mm aluminum H-profile for mounting, with 4 mm joint between panels

For optimal performance, walls are siliconized with silicone mastic and anchored with aluminum profiles to existing floors.

Steel DeltaWALL™

Rock Wool Insulation

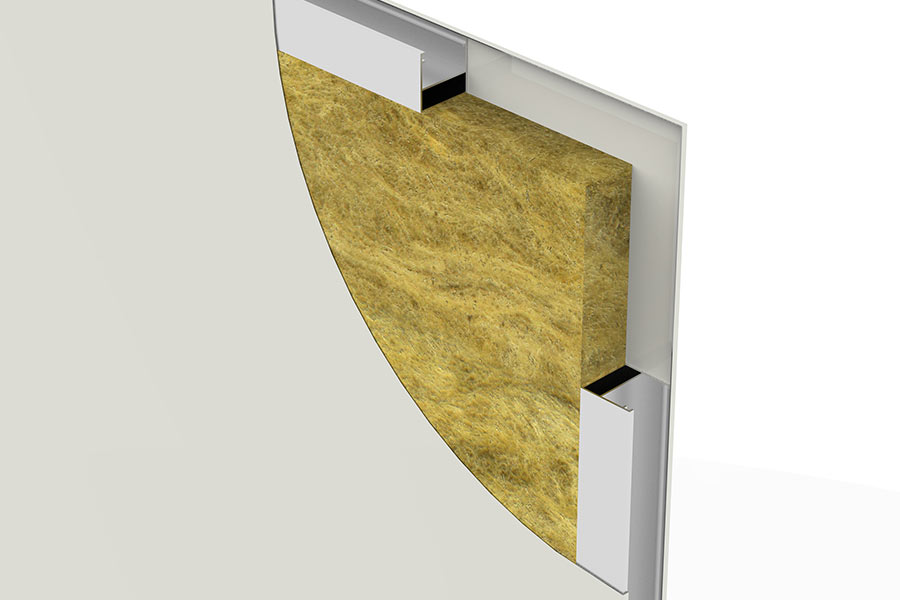

STEEL aluminum-coated rock wool insulation for sterile cleanroom modular panels are used in various industries. Used for walls, floors, ceilings and pharmaceutical doors, they offer advantages such as: excellent sound-absorbing properties, superior insulation to fiberglass, durable performance, resistance to deterioration and effective moisture management.

ROCKWOOL offers solutions for the insulation of all types of interior and exterior walls.

STEEL DeltaWALL™ ROCKWALL modular walls are composed of:

- 2 mm extruded aluminum inner frame, insulated with honeycomb aluminum or corrugated sheet metal

- Galvanized sheet metal exterior cladding, total thickness 48 mm

- Vertical 2 mm aluminum H-profile for mounting, with 4 mm joint between panels

For best results, STEEL DeltaWALL rock wool walls are siliconized with silicone mastic and attached to existing floors with aluminum profiles.

Steel DeltaWALL™

Honeycomb Insulator

STEEL aluminum modular panel honeycomb insulators are used in industries such as pharmaceutical, biomedical, chemical, cosmetic, food and hospital.

Used for walls, floors, ceilings, and pharmaceutical doors, they offer advantages such as light weight, rigidity, fire resistance, compressive and corrosion resistance, and flat surface.

STEEL DeltaWALL™ HONEYCOMB modular walls are composed of:

- 2 mm extruded aluminum inner frame, insulated with honeycomb aluminum or corrugated sheet metal

- Galvanized sheet metal exterior cladding, total thickness 48 mm

- Vertical 2 mm aluminum H-profile for mounting, with 4 mm joint between panels

For optimal performance, STEEL DeltaWALL honeycomb walls are siliconized with mastic and attached to existing floors with aluminum profiles.

Galvanized steel sheet panel for sterile cleanroom.

Modular galvanized steel sheet panels for sterile cleanroom

The modular galvanized steel sheet panels used by Delta2000, for the production of clean rooms, can be applied to: walls, ceilings, doors and floors.

The modular galvanized steel sheet panel is assembled by joining two 7/10-thick iron sheets, which are attached to a four-sided, extruded aluminum frame. Depending on the design requirements, the insulation materials placed between the laminate sheets can be:

- Self-extinguishing polystyrene (Euro class E)

- High-density rock wool

- Corrugated sheet metal

Classified by a wide range of peculiarities and advantages that make them ideal for cleanroom construction.

These benefits include:

- Fire and heat resistance

- Corrosion resistance

- Rigidity

- Lightness