Flexible modular ceiling

DeltaFURNITURES™ is the line of cleanroom cabinets manufactured by Delta2000, a company specializing in cleanroom design, manufacturing and installation.

Designed for contamination-controlled areas, these cabinets find application in numerous sectors, with a focus on projects dedicated to the hospital sector.

Delta2000 cabinets are assembled and milled by hand, edged with special machinery and made of durable HPL (high-pressure laminate), an ideal material for clean rooms.

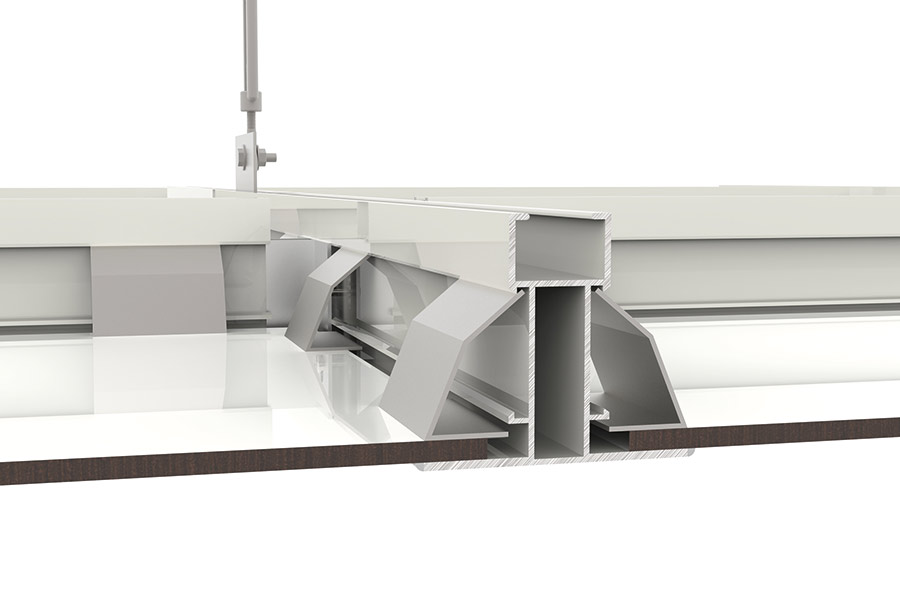

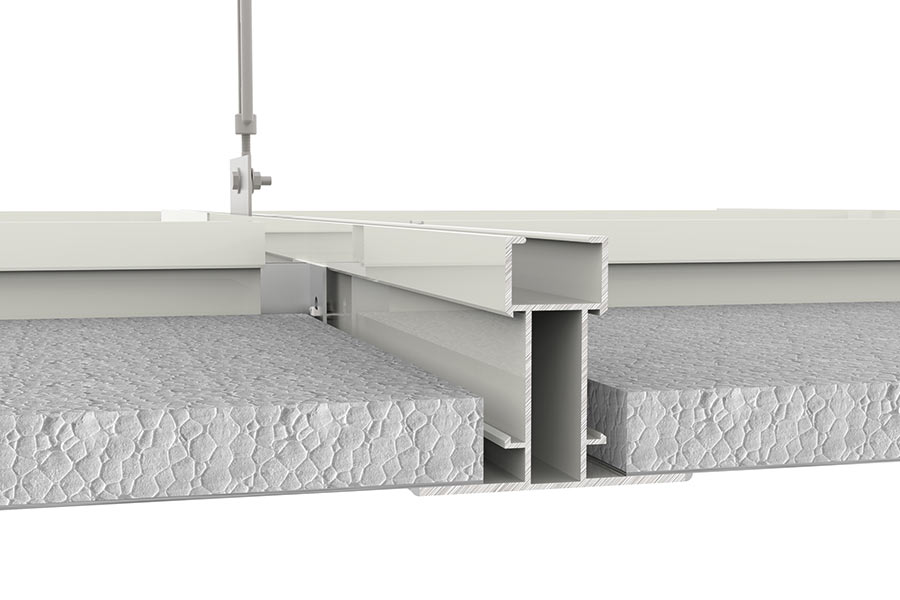

OMEGA DeltaCEILING™

False ceiling with Omega 65 profile plastic laminate 5mm

Ceilings with Omega Profile 65 Laminated Plastic Laminate 5 mm (art. no. FC-LAM5) from Delta2000 consist of a 65 mm anodized or pre-painted aluminum frame with 5 mm HPL panels for clean rooms. The materials are certified according to current standards.

Main features:

- Omega 65 aluminum profile

- 5 mm HPL panels

- Adjustable hanging in rigid threaded rods

- Joints with silicone mastic

- Aluminum locks

This lightweight, flat ceiling sits below the original ceiling, reducing the usable height, with aesthetic, heat-insulating, sound-insulating, or fireproofing functions, and allows systems to be contained in the space created.

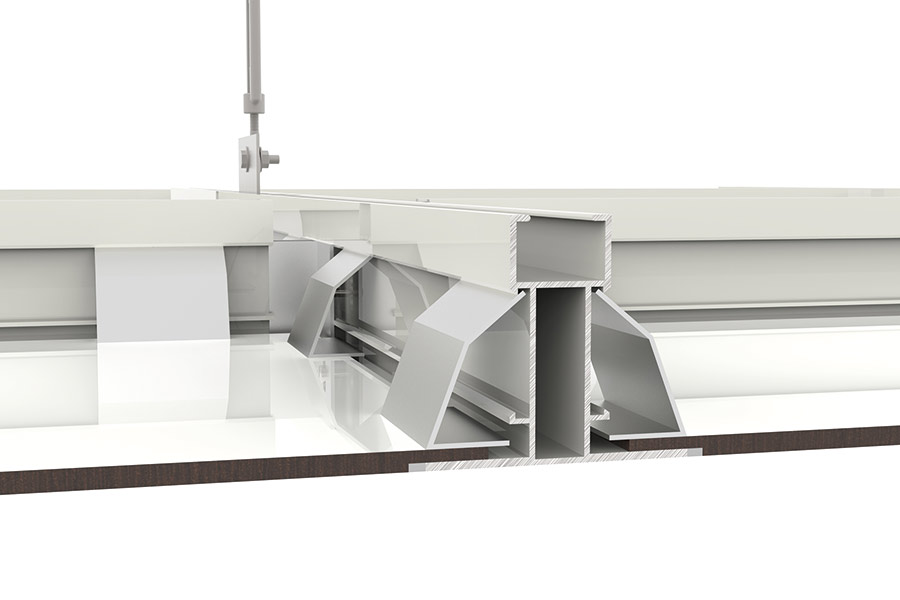

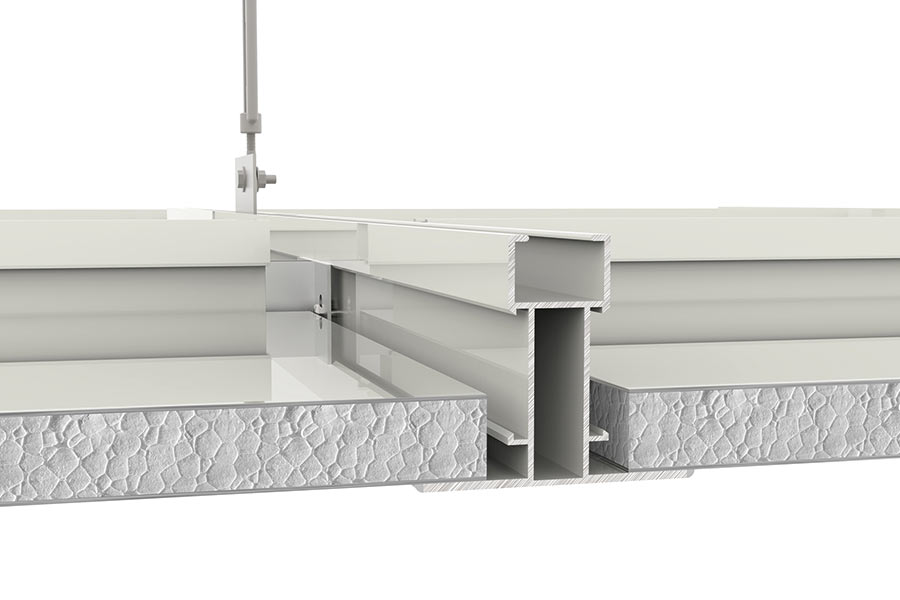

OMEGA DeltaCEILING™

False ceiling with Omega 65 profile plastic laminate 5 mm milled

Ceilings with Omega Profile 65 Plastic Laminate 5mm Milled (code FC-LAM5F) ceilings from Delta2000 consist of an anodized or pre-painted aluminum frame with 65mm exposed profile and cleanroom infill panels made of 5mm-thick, double-decorated plastic laminate, milled and sealed with silicone mastic to ensure flatness, tightness and cleanliness over time.

The panels are locked to the omega grid by specific springs. The structure includes adjustable pendanting in rigid threaded bars and aluminum locks.

The lightweight, flat ceiling is placed under the ceiling, reducing the usable height, and can serve aesthetic, heat-insulating, sound-insulating, and fireproofing purposes or to house installations in the created space. All materials are certified according to current regulations.

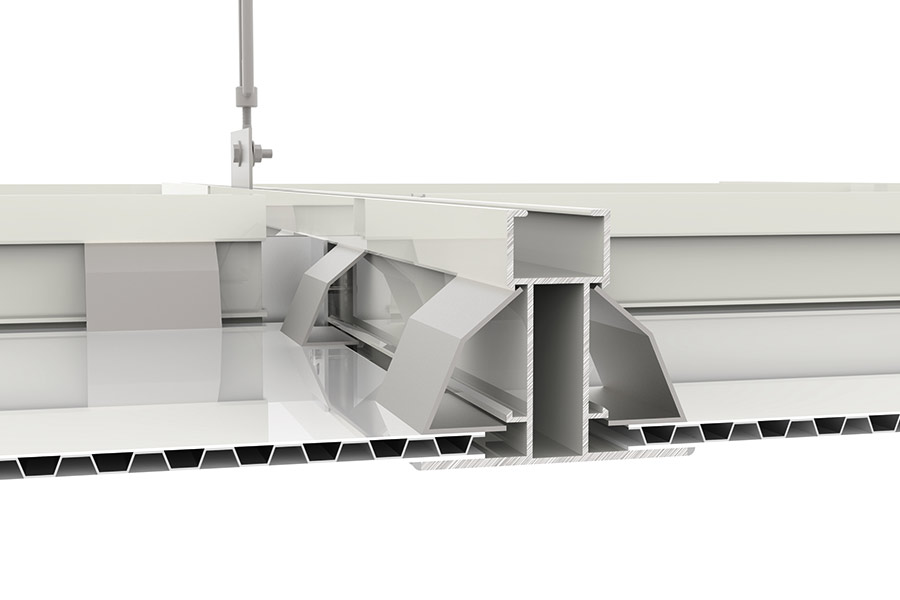

OMEGA DeltaCEILING™

False ceiling with 6 mm Omega 65 honeycomb profile

Delta2000’s 6 mm Omega 65 Honeycomb Profile Omega 65 ceilings (code FC-SA6) consist of an anodized or pre-painted aluminum frame with a 65 mm exposed profile and aluminum sandwich panels with 6 mm thick internal corrugated sheet metal, ensuring tightness and resistance to varying humidity and temperatures.

The panels are fixed by specific springs. The structure includes adjustable pendanting in threaded rods, silicone mastic joints and aluminum locks.

The lightweight, flat ceiling is installed under the ceiling, reducing the usable height, with aesthetic, heat-insulating, sound-insulating, fireproofing functions or to house systems in the space below. All materials are certified according to current regulations.

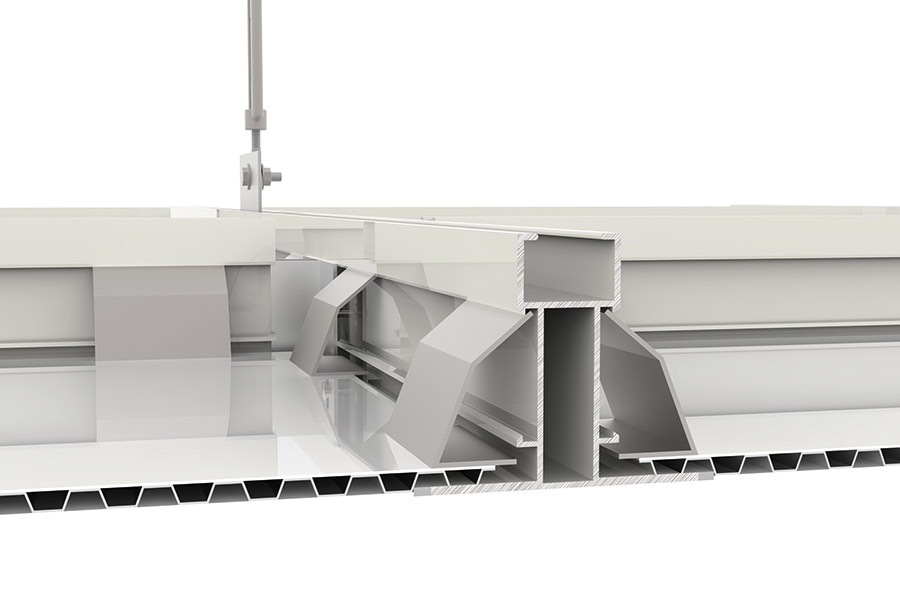

OMEGA DeltaCEILING™

Ceiling with Omega 65 honeycomb 6 mm milled profile

Delta2000’s 6 mm milled Omega 65 Honeycomb Profile Omega 65 ceilings (code FC-SA6F) are composed of an anodized or pre-painted aluminum frame with a 65 mm exposed profile and aluminum sandwich panels with 6 mm thick internal corrugated sheet, milled and sealed with silicone mastic to ensure flatness and tightness in environments with different humidity and temperature conditions.

The panels are fixed with specific springs. The structure provides adjustable pendanting, silicone mastic joints and aluminum locks.

The lightweight, flat ceiling is installed under the ceiling, reducing the usable height, and can have aesthetic, heat-insulating, sound-insulating, fireproofing functions or to house installations. All materials are certified according to current regulations.

OMEGA DeltaCEILING™

False ceiling with Omega 65 profile, polystyrene aluminum panel, aluminum 20 mm

Ceilings with Omega 65 Profile and 20 mm aluminum-polystyrene-aluminum panels (code FC-ALLPOS) from Delta2000 consist of an anodized or pre-painted aluminum frame with 65 mm exposed profile and sandwich panels with pre-painted aluminum sheet (7/10) and polystyrene insulation, suitable for environments with varying humidity and temperatures, providing good insulation.

The structure includes adjustable pendanting in threaded rods and silicone mastic joints.

The lightweight, flat ceiling can be installed under the ceiling, reducing the usable height, and can perform aesthetic, heat-insulating, sound-insulating, fireproofing functions or to house equipment. All materials are certified according to current regulations.

OMEGA DeltaCEILING™

False ceiling with Omega 65 profile, 20 mm polystyrene aluminum panel

False ceilings with Omega 65 Profile and 20 mm aluminum-polystyrene panels (code FC-ALLPOP) from Delta2000 have a 65 mm anodized or pre-painted aluminum frame and sandwich panels with pre-painted aluminum sheet (7/10) and polystyrene insulation, suitable for environments with varying humidity and temperatures, providing excellent insulation.

The structure provides adjustable pendanting and silicone mastic joints.

The lightweight, flat ceiling is installed under the ceiling, reducing the usable height, and can have aesthetic, heat-insulating, sound-insulating, fireproofing functions or to house installations. All materials are certified according to current regulations.

OMEGA DeltaCEILING™

False ceiling with Omega 65 profile, aluminum plasterboard panel

Delta2000’s ceilings with Omega 65 Profile and aluminum-plasterboard panels consist of a 65 mm anodized or pre-painted aluminum frame and sandwich panels with pre-painted aluminum sheet (7/10) and 12.5 mm plasterboard insulation, suitable for environments with varying humidity and temperatures for good insulation.

The structure provides adjustable pendanting and silicone mastic joints.

The lightweight, flat ceiling is installed under the ceiling, reducing the usable height, and can have aesthetic, heat-insulating, sound-insulating, fireproofing functions or to house installations. All materials are certified according to current regulations.

Certifications: ASTM E84-18b, ASTM International.

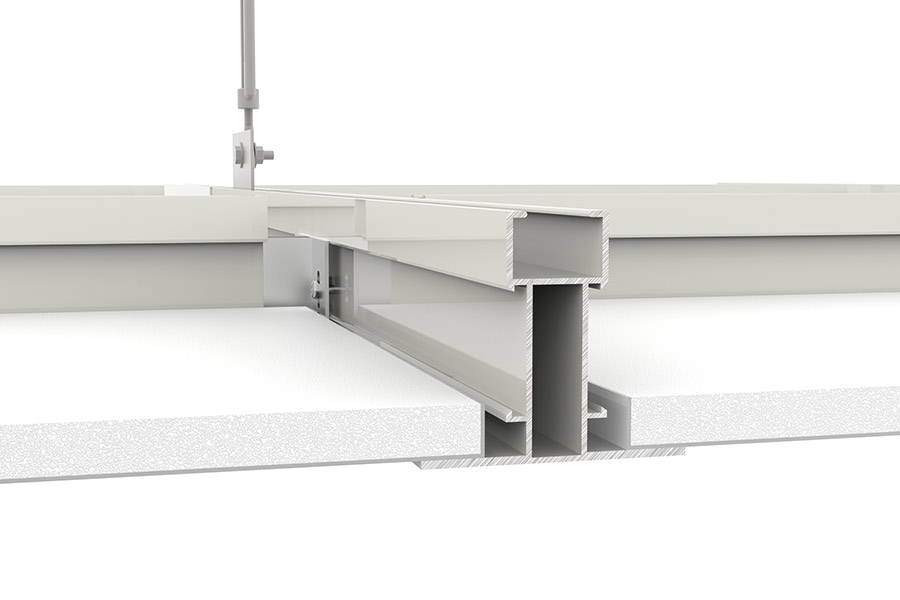

Flexible modular suspended ceilings for sterile environments.

OMEGA DeltaCeiling™

Features, uses and benefits

Delta2000‘s OMEGA DeltaCeiling range of cleanroom ceilings, manufactured by Delta2000, consist of an omega frame, with a 65-mm exposed profile made of anodized and/or pre-painted extruded aluminum, with cleanroom infill panels.

They can be produced in different solutions.

All materials used are certified according to applicable regulations.

Features and technical description

Available colors

Standard

Non-Standard

Delta2000 world leader

Cleanroom Design

During the design phase, the reference sector, type of use, and current regulations are taken into consideration in order to create a layout that meets the highest standards of efficiency and safety. In addition, the integration of the Clean Room into existing processes is also taken into account.

Cleanroom installation

Once designed, built, and tested, the Cleanroom is installed on site. We use our teams of qualified installers with a very high level of professionalism specific to the sector, who fine-tune all the specifications in the project.

Cleanroom Production

The characteristics of our production make our clean rooms unique in many ways: customization and the possibility of non-standard designs; flexibility in terms of timing; use of Italian and European components; and maximum punctuality in delivery.