This particular HPL laminated panel, made by Delta 2000, a company specializing in cleanroom design, production and installation, is intended for multiple sectors: pharmaceutical, biomedical, chemical, cosmetic and food. Not forgetting the structured projects for the hospital sector.

High-pressure laminated board consists of six to eight layers of Kraft paper impregnated with thermosetting resins and compacted. Decoration is done by means of special decorative paper, featuring a unique pattern or colorful hue.

The layers are compacted to generate a high-strength, dense, hard, durable and easy-to-clean surface that requires little maintenance. The use of thermosetting products, such as resin, allows the laminate panel to undergo the curing process due to the high temperatures applied.

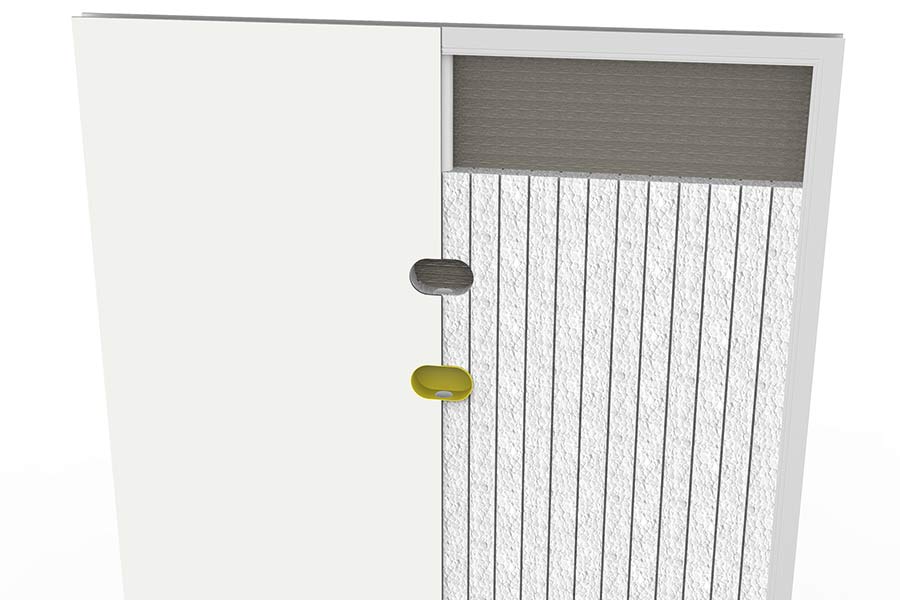

HPL DeltaWALL™

Insulating Polystyrene

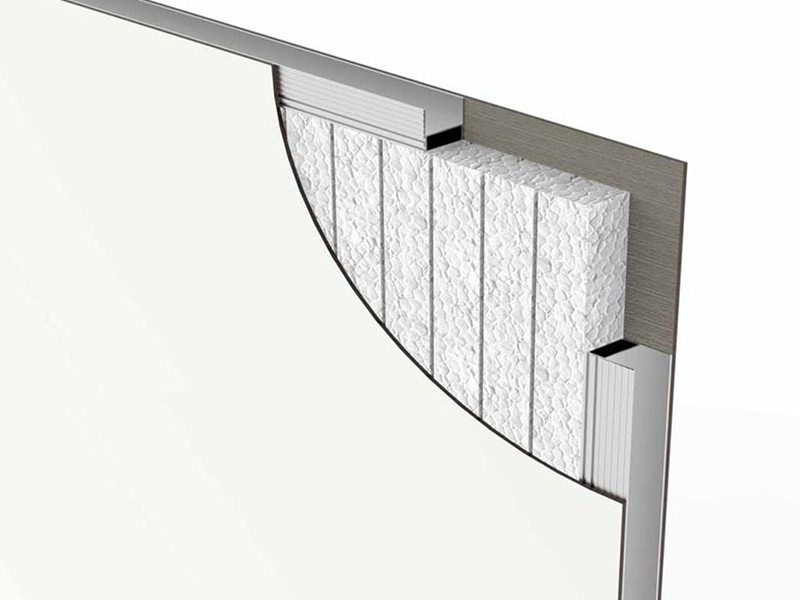

Delta 2000’s polystyrene insulation for HPL modular panels, ideal for cleanroom installation, are used in a variety of industries. They are used for walls, floors, ceilings and pharmaceutical doors.

Panels with sintered expanded polystyrene insulation (fire reaction class E) comply with UNI EN 13163 with CE marking, ensuring high insulation power, stability over time, vapor permeability, water resistance, as well as being impervious to mold and bacteria.

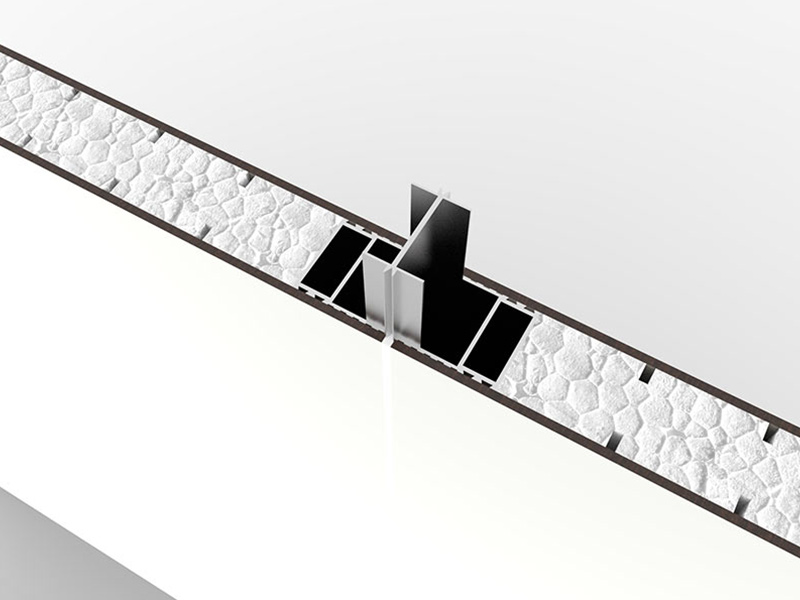

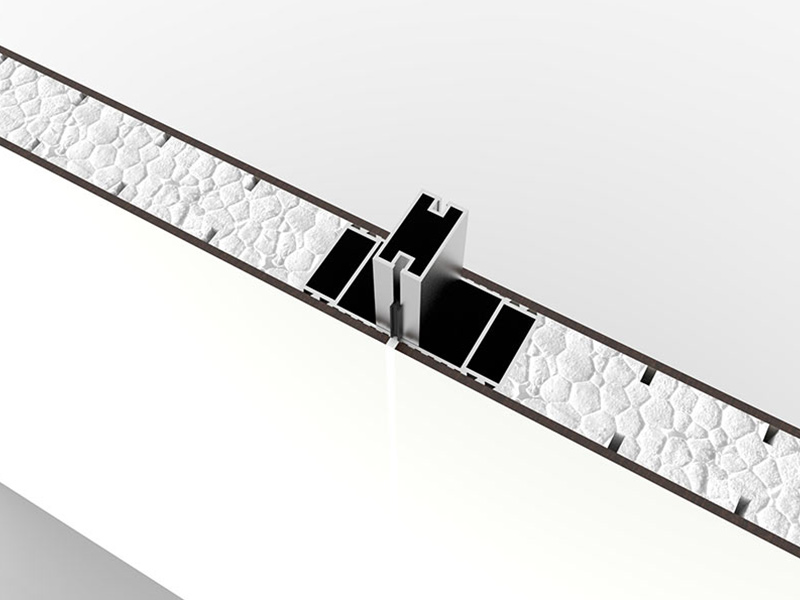

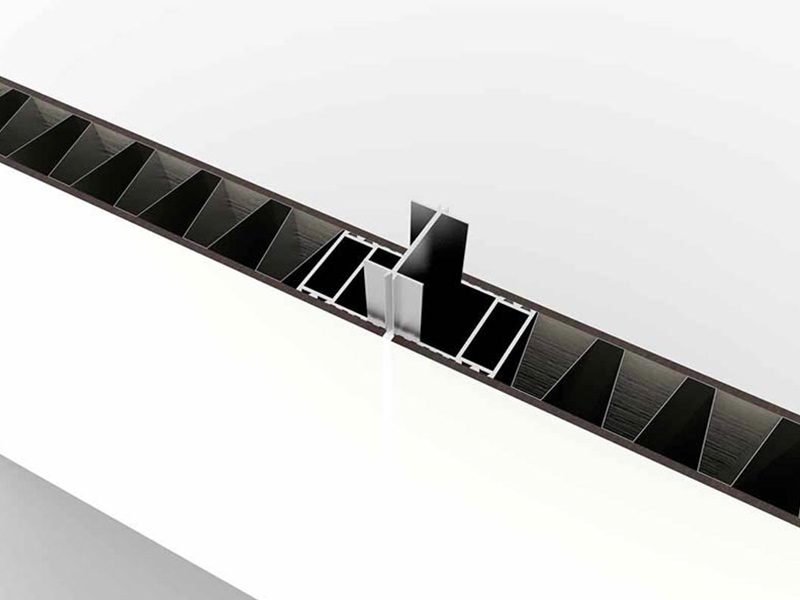

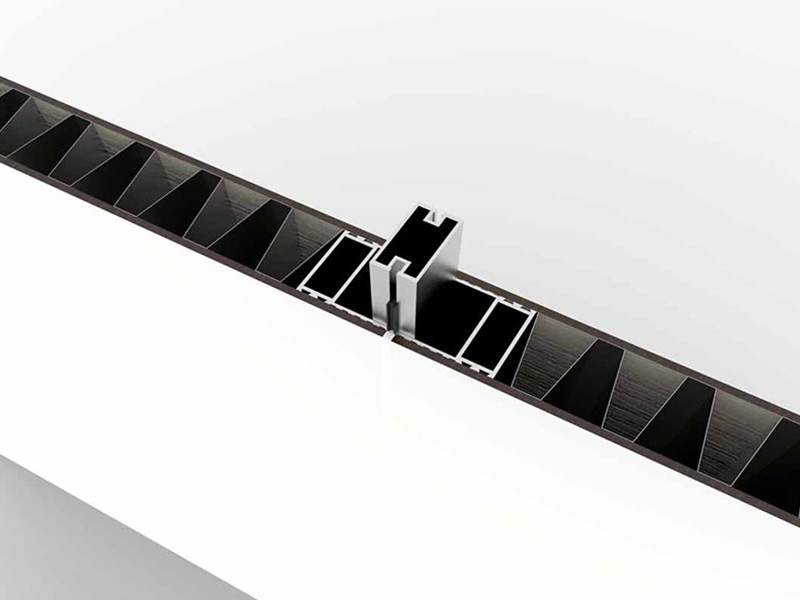

DeltaWALL™ Polystyrene HPL modular walls are composed of a 2 mm extruded aluminum frame with polystyrene insulation, 4 mm HPL laminate panel exterior cladding for a total thickness of 48 mm, and H-shaped aluminum mounting bar (2 mm), which allows up to a 4 mm joint between panels.

Installation involves siliconizing with mastic and finishing with aluminum profiles attached to existing floors, ensuring functionality and aesthetics.

HPL DeltaWALL™

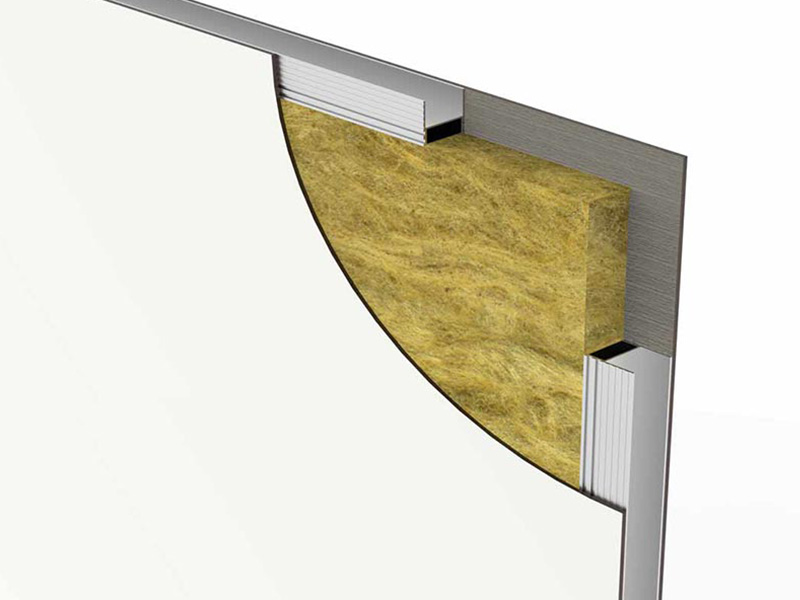

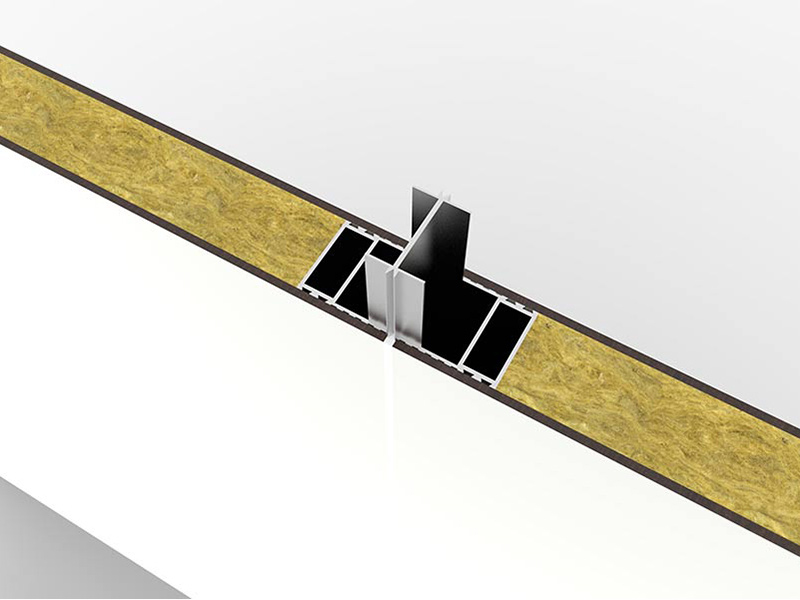

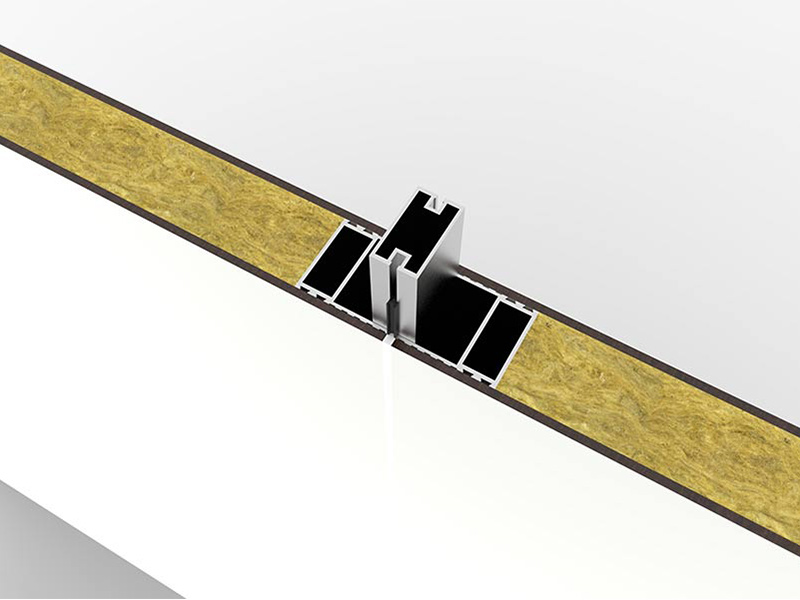

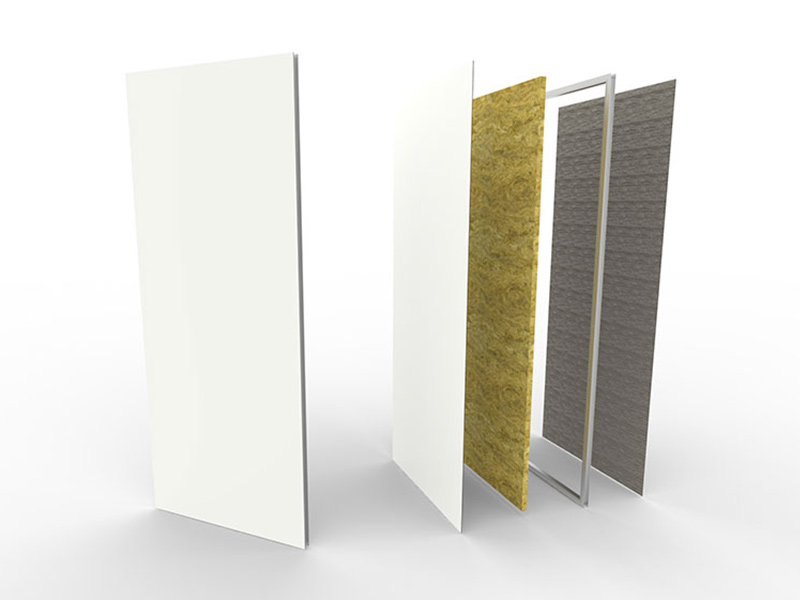

Rock Wool Insulation

Delta 2000’s aluminum-coated rockwool insulation is suitable for the same areas and applications as HPL modular walls, perfect for cleanroom due to its excellent sound-absorbing properties, high insulation value superior to fiberglass, long service life, and ability to shed moisture without deteriorating.

Rockwool’s DeltaWALLS™ HPL modular walls are made of 2 mm extruded aluminum frame, insulated with oriented fiber rock wool, 4 mm HPL laminated panel cladding (total thickness 48 mm) and H-shaped mounting bar (2 mm) with up to 4 mm joint.

Silicone mastic and rough aluminum profiles complete the system to ensure optimal insulation and finish.

HPL DeltaWALL™

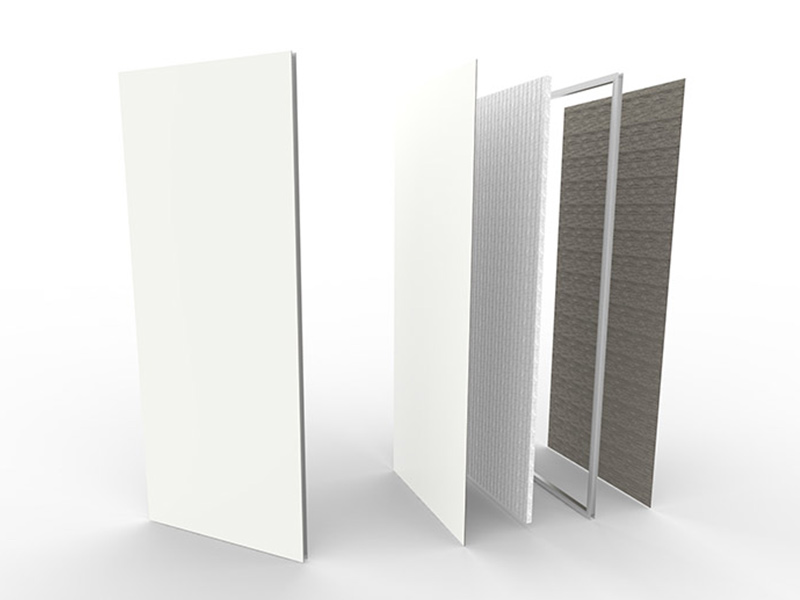

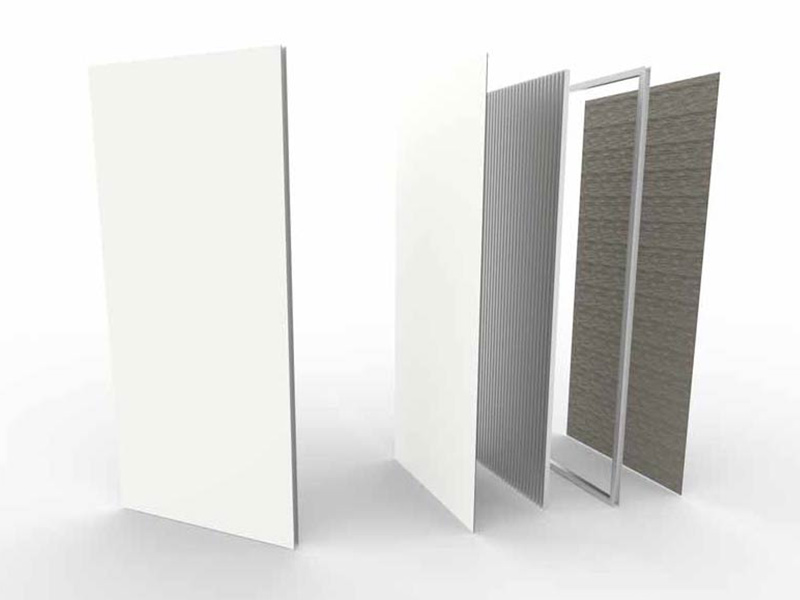

Honeycomb Insulator

Delta 2000’s aluminum honeycomb insulators, used in cleanroom-compatible industries, offer light weight, rigidity, fire resistance, compression, tensile strength, corrosion resistance and a perfectly smooth surface.

DeltaWALL™ Honeycomb HPL modular walls feature 2 mm extruded aluminum frame with honeycomb or corrugated sheet structure, 4 mm HPL laminated panel exterior cladding (total panel thickness 48 mm) and H-shaped vertical bar (2 mm) with up to 4 mm joint.

Siliconing with mastic and aluminum profiles attached to floors ensure the solidity and perfect finish.

High Pressure Laminate, also known as HPL (High Pressure Laminate), is produced through a process that is divided into several pressurized and thermal steps.

Layered HPL

Features, uses and benefits for indoor environments

HPL laminate is an ideal material for indoor environments such as clean room, operating under specific climatic conditions. It is not recommended for outdoor environments. It consists internally of one or more layers of cellulosic fibers impregnated with phenolic resins, while the surface is made of decorative cellulosic fibers impregnated with thermosetting resins.

The main advantages of high-pressure laminated panel include:

- High aesthetic customization

- Scratch and impact resistance

- Availability in multiple colors and thicknesses

- Quick and easy maintenance

These panels are the perfect choice for creating and covering a modern and functional clean room.