This particular modular aluminum panel, made by Delta 2000, a company specializing in the design, production and installation of aseptic chambers(cleanrooms), is intended for multiple sectors: pharmaceutical, biomedical, chemical, cosmetic, food and hospital.

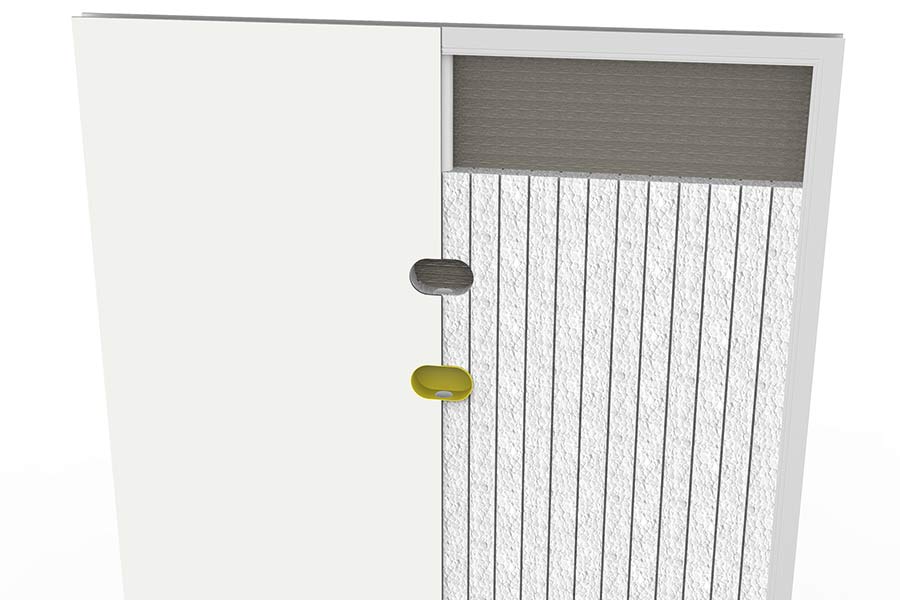

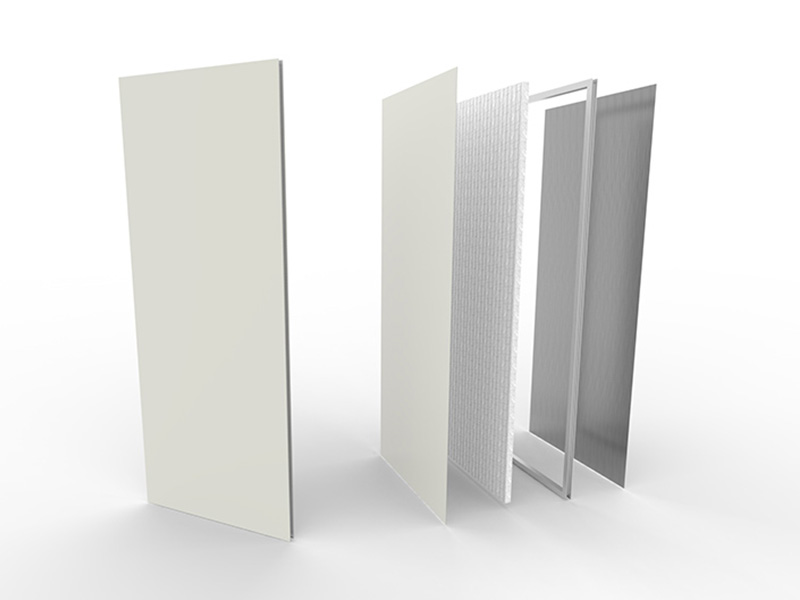

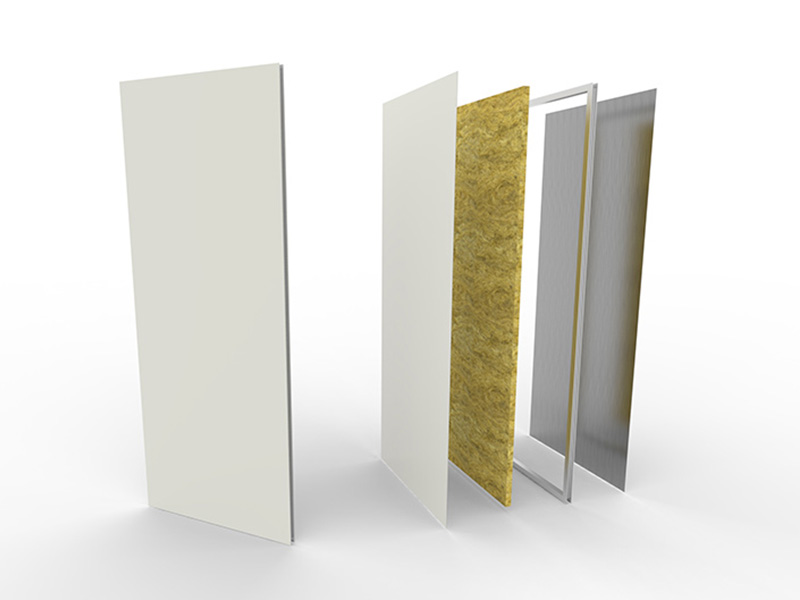

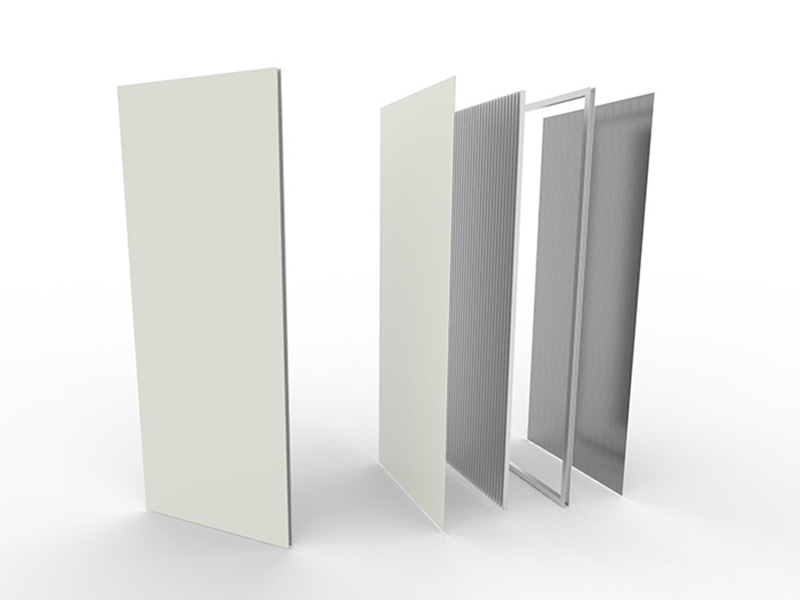

Aseptic Room Aluminum Panel DeltaWALL: Modular aluminum panels for , used for walls, ceilings, doors and floors, consist of two 12/10-thick aluminum sheets assembled on a four-sided extruded aluminum frame.

Depending on the design requirements, the insulating materials between the laminate sheets can be:

- High DensityPolystyrene (Polystyrene)

- High-density mineral rock wool(Rockwool)

- Honeycomb aluminum(Honeycomb)

Aluminum DeltaWALL™

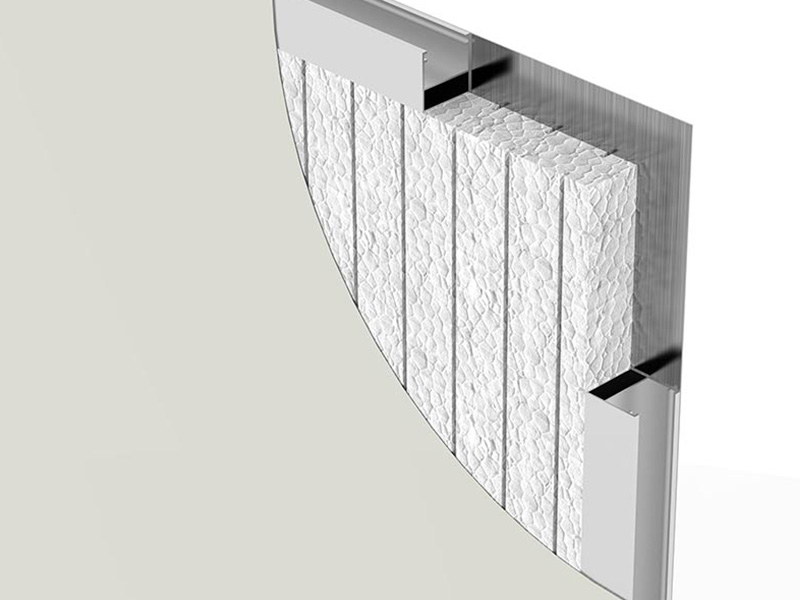

Insulating Polystyrene

DeltaWALL™ aluminum modular panels with class E closed-cell sintered expanded polystyrene insulation comply with UNI EN 13163 standards with CE marking. These panels are suitable for aseptic rooms(cleanrooms) that require good mechanical strength.

Aseptic chamber aluminum panel DeltaWALL main advantages:

- High insulation power

- Stability over time

- Water vapor permeability

- Water resistance

- Impervious to mold and bacteria

The modular walls are composed of:

- Inner frame made of 2 mm thick raw extruded aluminum, insulated with polystyrene;

- Exterior cladding of 12/10 aluminum sheet metal, with 48 mm total panel;

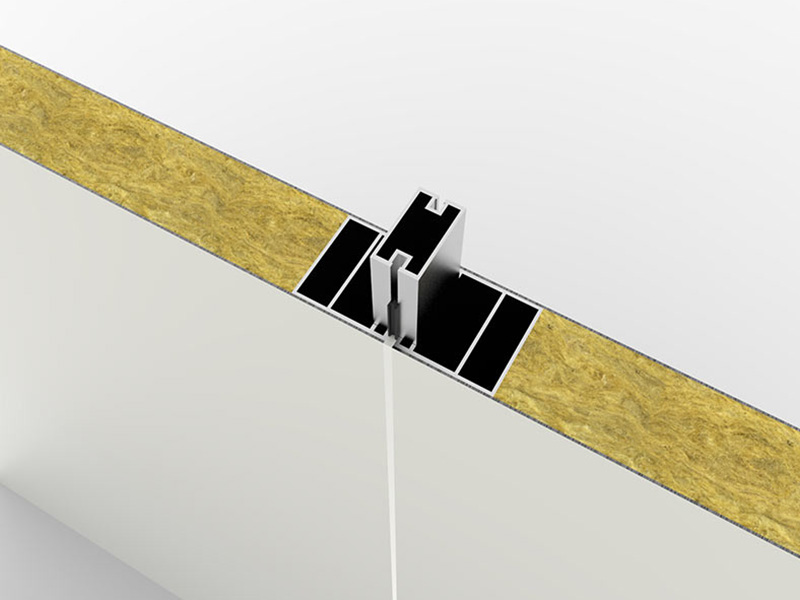

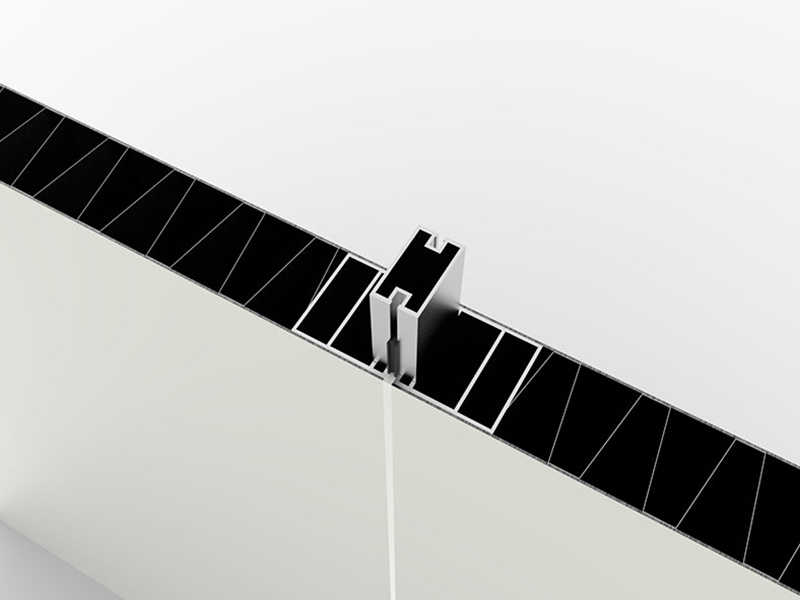

- Vertical H-shaped aluminum extrusion bar (2 mm thick) for mounting, with maximum 4 mm joint;

- Silicone mastic and rough aluminum profiles ensure durable and functional installation in cleanrooms.

Aluminum DeltaWALL™

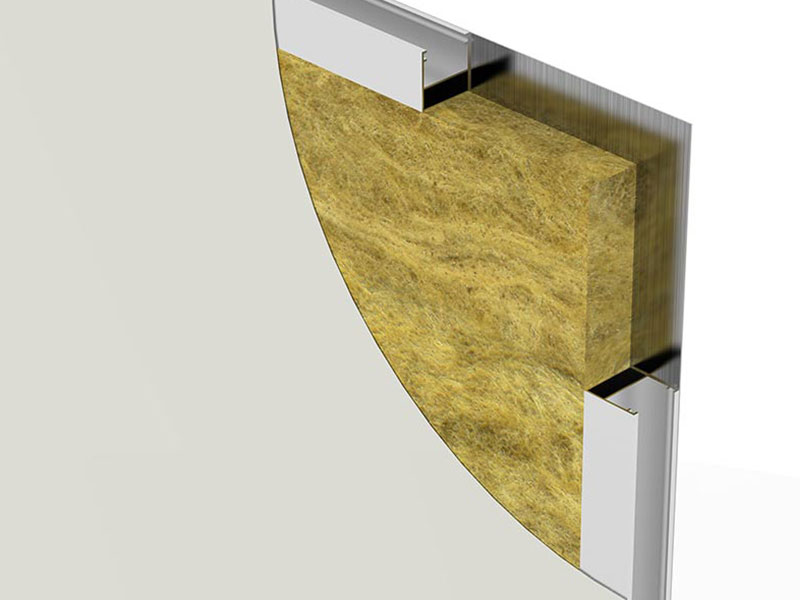

Rock Wool Insulation

Rock wool insulation for aluminum modular panels is used in many aseptic chambers used in the pharmaceutical, biomedical, chemical, cosmetic, food and hospital industries. Rock wool insulation is applied to walls, floors, ceilings and pharmaceutical doors.

Rock wool insulation advantages:

- Excellent sound-absorbing properties;

- Superior insulation compared to fiberglass;

- Long-lasting performance;

- It does not deteriorate;

- Allows moisture to escape.

These walls are formed by:

- Inner frame made of 2 mm raw extruded aluminum, insulated with rock wool;

- Outer cladding of 12/10 aluminum sheet, total thickness 48 mm;

- Vertical H-shaped aluminum mounting bar (2 mm thick).

The walls are siliconized and anchored to existing floors to preserve functionality and aesthetics in cleanrooms.

Aluminum DeltaWALL™

Honeycomb Insulator

Aluminum modular panel honeycomb insulators are widely used in aseptic chambers in various industries and are used for walls, floors, ceilings and pharmaceutical doors.

Characteristics of honeycomb insulation:

- Lightness

- Rigidity

- Fire resistance

- Compressive, tensile and corrosion resistance

- Flat surface

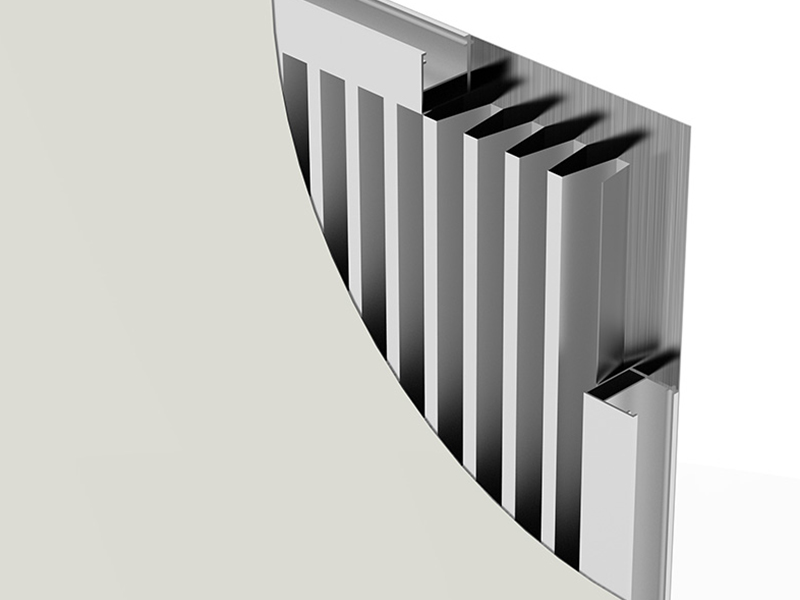

Aluminum DeltaWALL™ HONEYCOMB walls are composed of:

- Inner frame made of 2 mm extruded aluminum, insulated with honeycomb aluminum;

- Outer coating aluminum sheet 12/10 (total thickness 48 mm);

- Vertical H-shaped aluminum mounting bar (2 mm);

Silicone mastic and aluminum profiles ensure the insulation and aesthetics of the cleanroom.

Aseptic chamber: DeltaWALL aluminum panel used for cleanroom production.

Modular aluminum panels

12/10 prepainted aluminum sheet metal

Delta 2000 aluminum modular panels for aseptic chambers (cleanrooms) have advantageous technical features:

- Fire and high temperature resistance;

- High corrosion resistance;

- Excellent stiffness;

- Moisture impermeability.

Prepainted 12/10 aluminum sheet is used to ensure durability and optimal performance in cleanrooms of various industries.