GLAZED DeltaWALL™ glass walls, made by Delta 2000, a company specializing in the design, production and installation of cleanrooms and aseptic cleanrooms, are intended for multiple sectors: Pharmaceutical, Biomedical, Chemical, Cosmetic and Food.

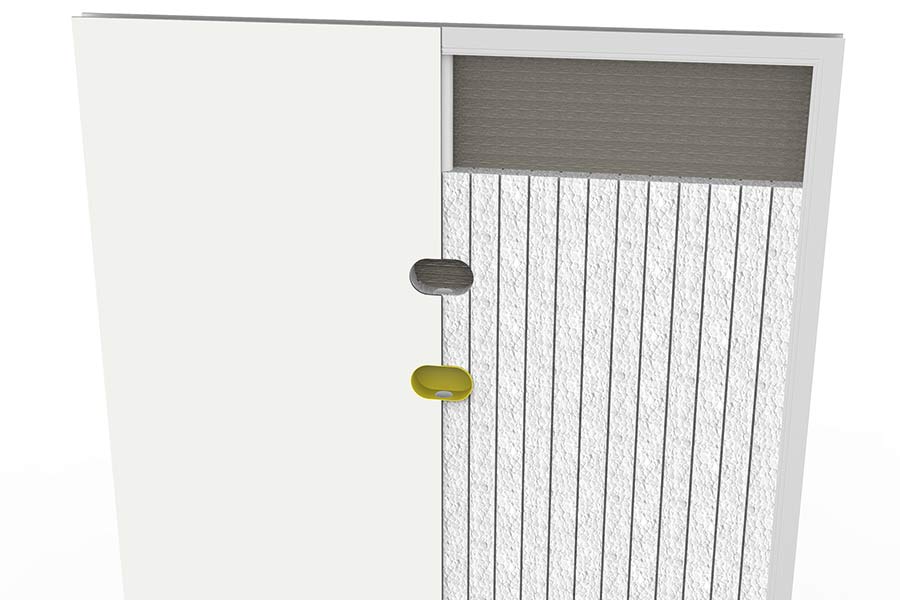

Cleanroom aseptic wall glazed DeltaWALL: Cleanroom glazed walls provide maximum transparency and flexibility of use due to unique and innovative design.

Cleanroom GLAZED DeltaWALL™ are divided into three systems according to their modes of use:

- The LIGHT line ideal for rooms where you want to create a large glass area

- The CLEAN line coplanar with the elements of the DELTA wall system, ensures compliance with ISO standards of aseptic cleanrooms.

The glazed wall with 55 profile structure allows the insertion of glazed surfaces, within the wall module, thanks to the adaptable nodal.

Glazed DeltaWALL™

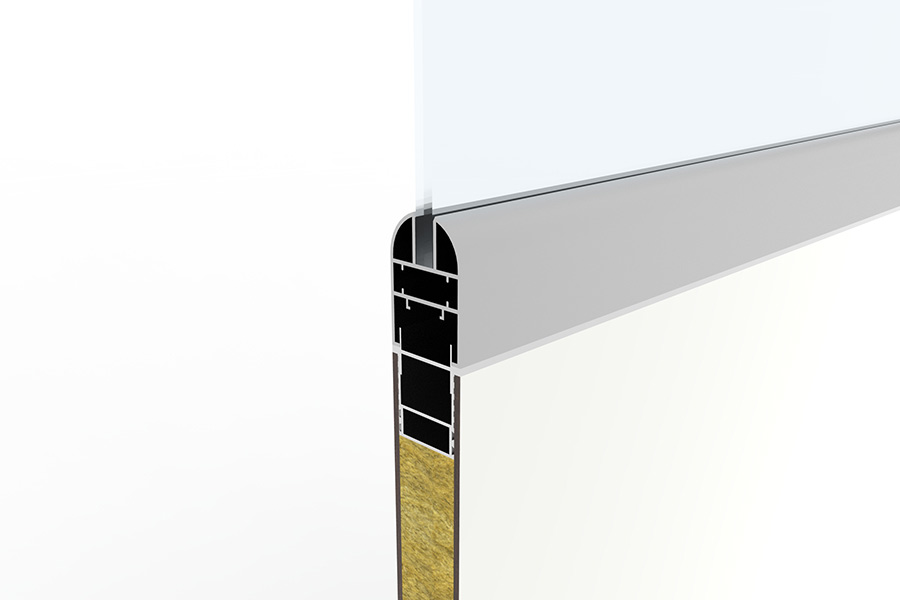

LIGHT glazed wall

GLAZED DeltaWALL LIGHT aseptic cleanroom walls are used for numerous applications and in a variety of industries.

GLAZED DeltaWALL LIGHT walls are made of 6 + 6 mm double safety glass, with a total thickness of 12 mm.

The glass is installed on anodized or painted extruded aluminum profiles and has the following characteristics:

- Width 2mm

- Joints between double-glazed panel and panels with retractable H-profiles, 2mm wide in unfinished aluminum

- Visual joint of 4mm between panels, siliconized with silicone mastic with total thickness of 48mm

Laminated safety glass is made by assembling two or more layers of glass, with one or more sheets of plastic material or interlayer (PVB, PU, PC, SGP, etc.), in order to achieve greater impact resistance.

The plastic film prevents the shatterproof glass from dispersing its fragments in the event of breakage, preventing splinter injuries and delaying or preventing intrusion by malicious intruders.

Glazed DeltaWALL™

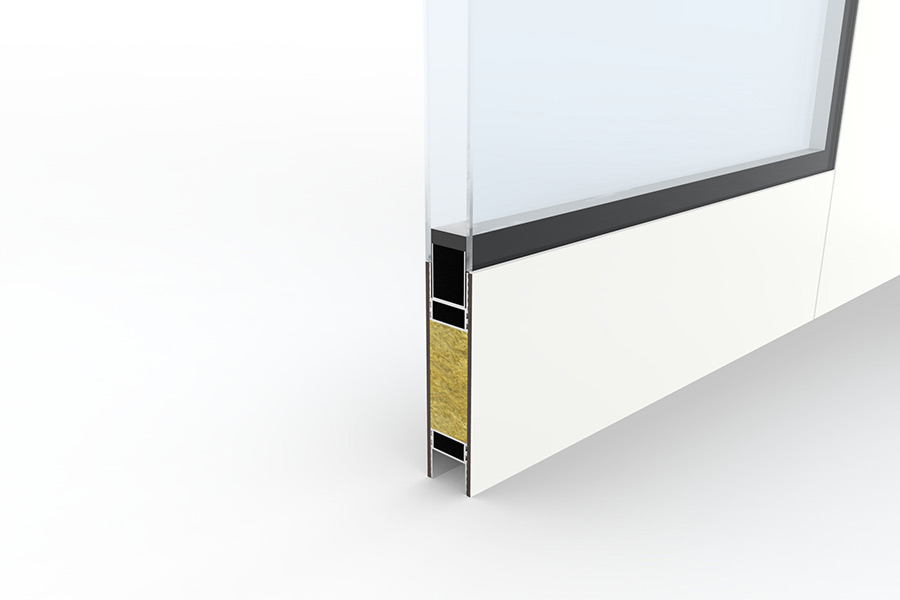

CLEAN glazed wall

GLAZED DeltaWALL CLEAN walls for aseptic cleanroomare double-glazed panel walls with an aluminum back interior frame having the following characteristics:

- Right angles

- Dehydrating salts

- Double safety glass, 3 + 3 mm thick

- Visual joint of 4 mm between panels

The double-glazed panel consists of rough aluminum U-bent profiles, having a thickness of 2mm and a visual joint between the panels of 4mm. Silicon-coated with silicone mastic, having a total thickness of 48mm.

Double glazing is insulating glass consisting of two or more paired panes of glass, separated by a cavity of dehydrated air or gas, the perimeter of which is usually composed of a lightweight metal frame, subjected to double sealing.

The composition and characteristics of the glass, which makes up an insulating glass unit, can be different depending on the thermal insulation and soundproofing requirements to be achieved.

In the gap between glass is usually dehydrated air or a noble gas, such as Argon or Krypton, which enhances thermal insulation performance.

Glazed DeltaWALL™

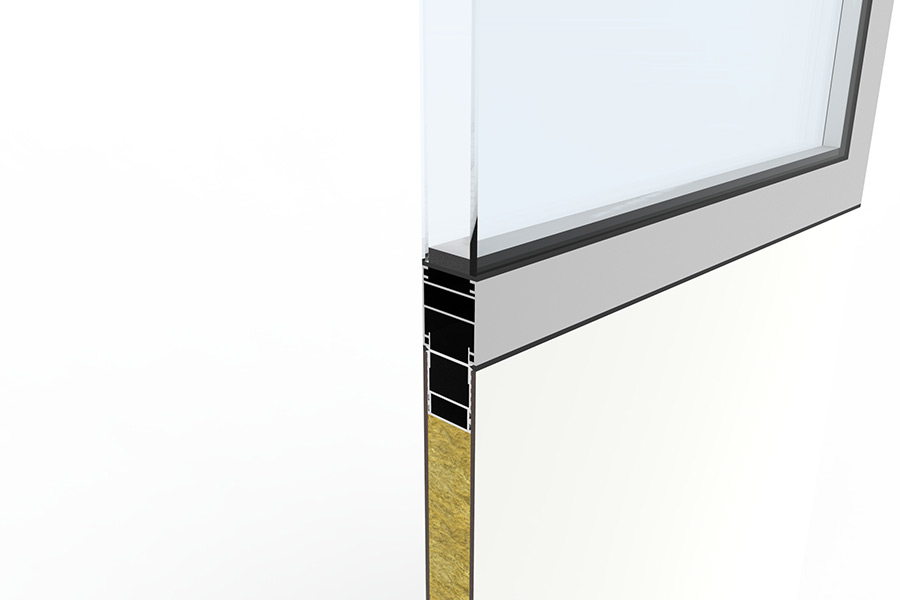

Glazed wall with "55" profile

GLAZED DeltaWALL 55 walls,consist of a double-glazed panel made of double-glazed wall having the following characteristics:

- Aluminum inner frame

- Right angles

- Dehydrating salts

- Double safety glass, with a thickness of 3 + 3 mm.

The safety glass is installed on a 55 mm H-shaped extruded aluminum outer frame.

GLAZED DeltaWALL 55 glazed walls possess joints between the double-glazed panel and the panels with 2mm wide retractable H-profiles made of raw aluminum, visual joint between the panels of 4mm, siliconized with silicone mastic of total thickness 48mm.

Double glazing is insulating glass consisting of two or more paired panes of glass separated by a cavity of dehydrated air or gas, the perimeter of which is usually composed of a lightweight metal frame subjected to double sealing.

The composition and characteristics of the glass, which makes up an insulating glass unit, can be different depending on the thermal insulation and soundproofing requirements to be achieved.

In the gap between glass is usually dehydrated air or a noble gas, such as Argon or Krypton, which enhances thermal insulation performance.

Cleanroom Aseptic Glazed DeltaWALL Wall: Certifications

Glazed cleanroom walls for aseptic cleanrooms

Elegance and transparency for the clean room

Glazed elements for clean rooms, used by our company, are composed of safety-certified glass having different compositions, depending on certain factors such as:

- Glass thickness

- Dimensions

Various finishes and accessories are also available, such as:

- Magnetically operated curtains

- Automated curtains