Cleanroom DeltaDoors™

Doors for clean rooms

DeltaDOOR cleanroom doors, manufactured by Delta2000, are designed for use in contamination-controlled areas. The DeltaDOOR range includes pharmaceutical doors designed by Delta2000, with special features that enhance their quality and aesthetics.

Doors can be installed on DeltaWALL wall panels or mounted directly on existing walls.

They also include devices to dispose of doors that fall to the floor upon closing, for increased air pressure.

All doors in the DeltaDOOR range are designed and developed according to customer requirements and focused on an end use, suitable for each specific type of industry.

Each element is developed with absolute respect for hygiene, to avoid contamination by harmful particles and to control the cleanroom atmosphere in terms of atmospheric pressure and level of pollutants.

Cleanroom DeltaDOORS™

Doors 1 leaf

DeltaDOORS™ 1-leaf doors excel in cleanrooms with limited space. They control critical environmental parameters and block contaminating particles.

Features:

- Frame: rough extruded aluminum, 2 mm thick.

- Surfaces: HPL, aluminum, steel.

- Interior: polystyrene, rock wool or honeycomb.

- Silicone application for aesthetic and functional excellence.

Ideal for the pharmaceutical, biomedical, chemical, cosmetic, food, hospital sectors. Flexible on DeltaWALL or pre-existing walls, with custom cleanroom kits.

Concealed magnets for quick and safe transits; integrated air grilles with flush profile.

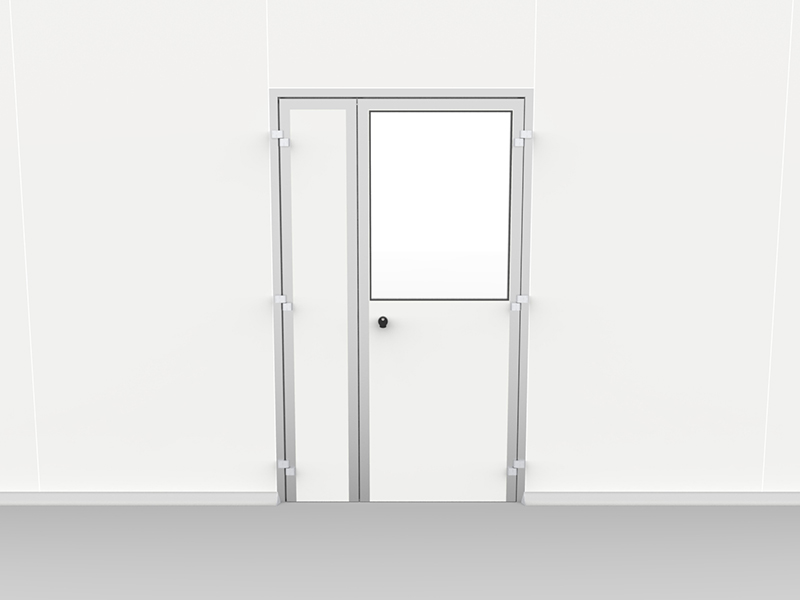

Cleanroom DeltaDOORS™

Doors 1 and a half doors

DeltaDOORS™ 1-and-a-half leaf doors are ideal for closed contamination-controlled environments such as cleanrooms with limited space. They maintain strict temperature, humidity and pressure, preventing contamination by harmful particles.

Main features:

- Frame made of 2 mm rough extruded aluminum.

- Cladding: HPL, aluminum or steel.

- Insulation: polystyrene, rock wool or honeycomb.

- Siliconate with mastic for aesthetics, insulation and functionality.

Designed for pharmaceutical, biomedical, chemical, cosmetic, food and hospital sectors. Can be installed on DeltaWALL panels or existing walls. Include specific accessories for cleanroom integration. Equipped with hidden magnets for fast and secure opening/closing, and airflow transit grilles, with smooth surface flush with door.

Cleanroom DeltaDOORS™

2 leaf doors

DeltaDOORS™ 2-leaf doors are designed for cleanrooms and controlled environments, ideal for large areas with high demands. They control temperature, humidity, pressure and prevent particulate contamination.

Main features:

- Frame: rough extruded aluminum, 2 mm.

- Coatings: HPL, aluminum, steel.

- Insulators: polystyrene, rock wool, honeycomb.

Treated with silicone coating for optimal aesthetics, insulation and performance. Suitable for pharmaceutical, biomedical, chemical, cosmetic, food and hospital. Compatible with DeltaWALL or existing walls, with dedicated accessories for integrated cleanrooms.

Includes built-in magnets for quick/secure closure and ventilation grilles, with smooth finish.

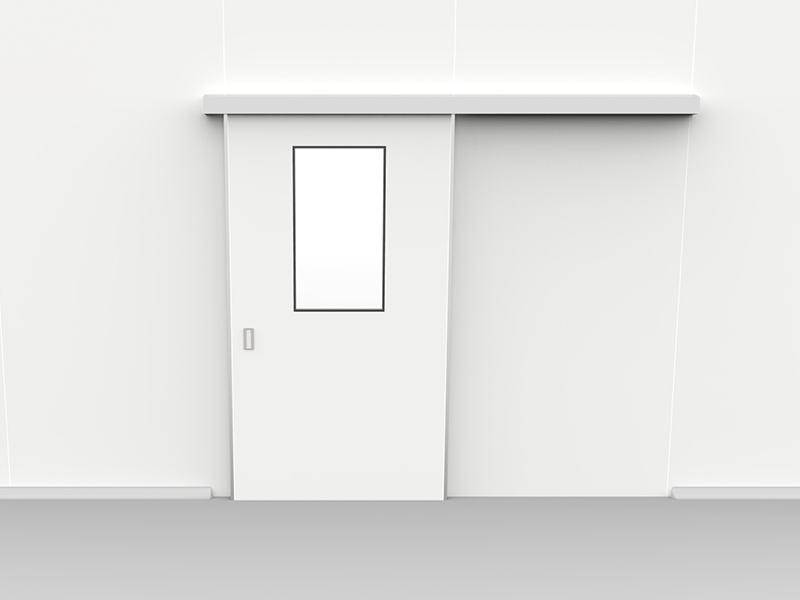

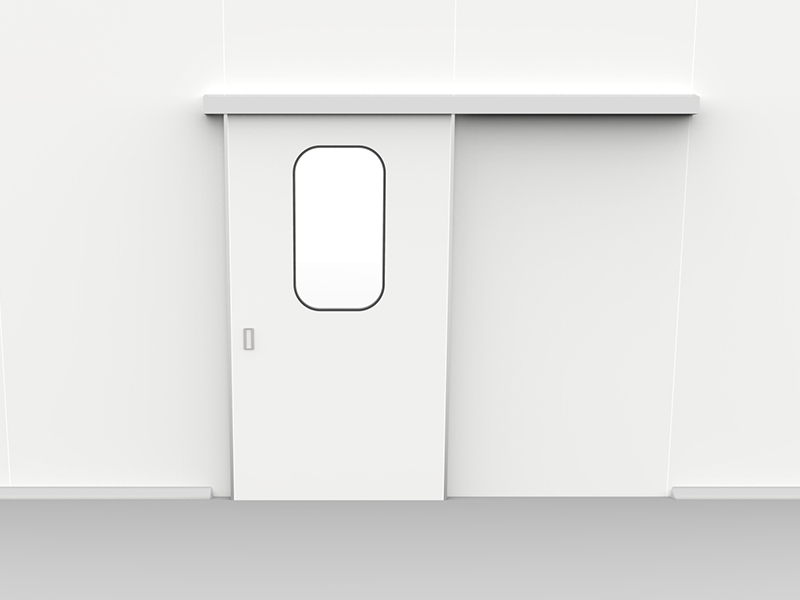

Cleanroom DeltaDOORS™

Sliding doors 1 leaf

DeltaDOORS™ 1-leaf sliding doors adapt to cleanrooms with tight spaces, where casements do not fit but intense passage is needed. They provide control of temperature, humidity, pressure and zero particulate contamination.

Technical characteristics:

- Frame: rough extruded aluminum (2 mm).

- Finishes: HPL, aluminum or steel.

- Filler: polystyrene, rock wool, honeycomb.

- Silicone sealing for maximum performance.

For pharmaceutical, biomedical, chemical, cosmetic, food and hospital industries. Mounting on DeltaWALL or standard walls, with customized cleanroom accessories.

Built-in magnets ensure quick and secure access; dedicated airflow grilles maintain flush surfaces.

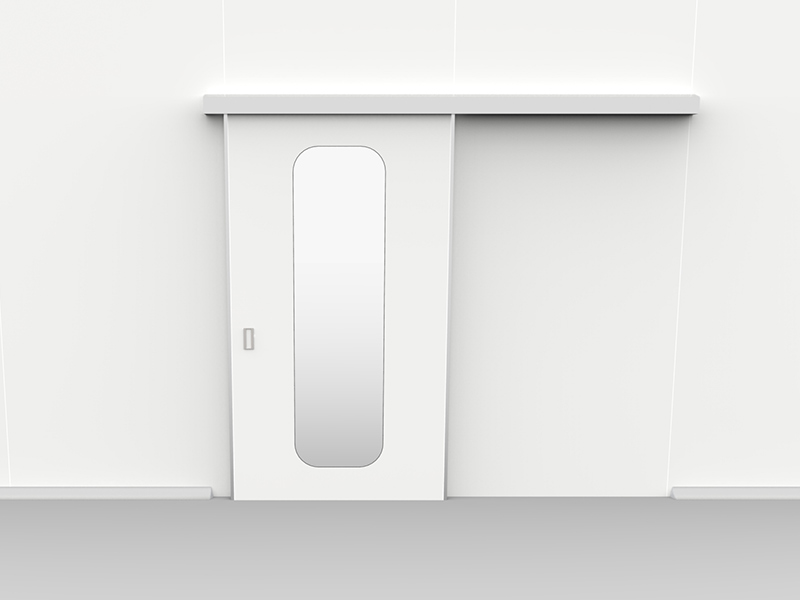

Cleanroom DeltaDOORS™

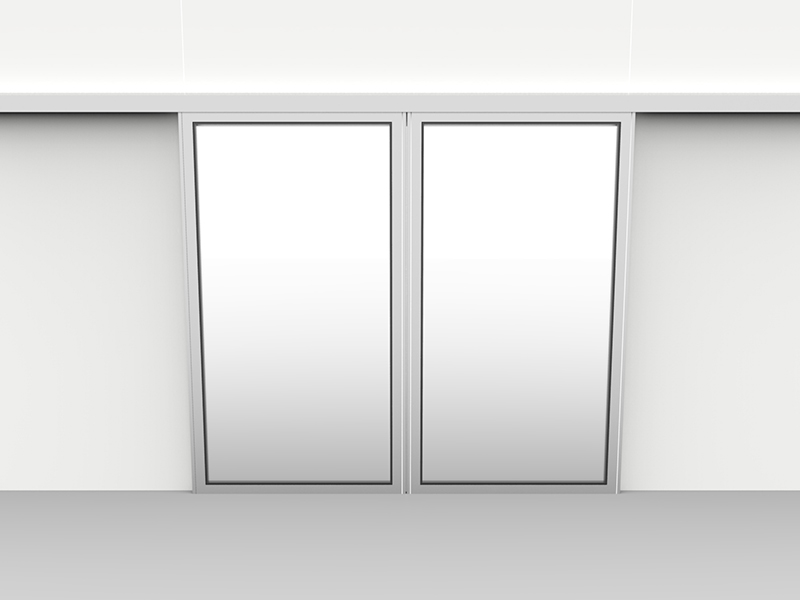

Sliding doors 2 leaves

DeltaDOORS™ 2-leaf sliding doors are ideal for cleanrooms and controlled environments in confined spaces where swinging doors are impractical but frequent and safe passage is essential. They maintain high standards of temperature, humidity and pressure, effectively preventing contamination by particles harmful to interior operations.

Door features:

- Frame made of 2 mm thick raw extruded aluminum.

- Coatings available: HPL, aluminum or steel.

- Insulation materials: polystyrene, rock wool, honeycomb.

- Treated with silicone mastic for aesthetic, thermal and operational superiority.

Developed for pharmaceutical, biomedical, chemical, cosmetic, food and hospital sectors. Can be attached to DeltaWALL panels or directly to existing walls, with custom accessories for seamless integration into the cleanroom. Equipped withmagnets hidden in the frame for quick, safe and intuitive opening and closing-perfect for staff in aseptic areas. Include custom-made transit grilles for airflow between rooms, with flush edges for a smooth, hygienic finish.

Cleanroom DeltaDOORS™

Counters

DeltaDOORS™ four-sided frame doors are optimized for cleanrooms and cramped spaces, ideal for cable passages, bakeries or warehouses. Raised so as not to alter flooring, they preserve control over temperature, humidity, pressure and contaminant particles.

They consist of:

- Frame: rough extruded aluminum (2 mm).

- Coatings: HPL, aluminum, steel.

- Insulators: polystyrene, rock wool, honeycomb.

- Siliconates for aesthetics, insulation, and reliability.

§For the pharmaceutical, biomedical, chemical, cosmetic, food and hospital sectors. Can be installed on DeltaWALL or walls, with customized cleanroom accessories.

Integrated magnets ensure quick and safe access; air flush grilles support sterile ventilation.

Features and technical description

Aluminum corrugated sheet Density 116 kg/m³, Rock wool Density 120 kg/m³, Polystyrene Flexural strength KPa > 250

Certifications

Available colors

Standard

Non-Standard

DeltaDOORS™ Accessories

The DeltaDOOR range designed by Delta2000 offers many types of doors, including asymmetrical or symmetrical swinging doors, single-leaf doors, double-leaf doors, sliding doors, hatches, and hatch doors.

All doors are designed with the consideration that they will be used for uncontaminated aseptic and sterile environments. All Delta2000 doors are manufactured and assembled with an aluminum inner radial frame, retractable door, external or internal hinges, and insulation in your choice of polystyrene, rock wool, or honeycomb.

Door panels with exterior cladding are available with the option of HPL, aluminum, galvanized steel, PVC cladding or double glazing. All doors are equipped with automated or manual operating mechanisms.